Rikici na 0.05mm Kauri FeCrAl waya juriya

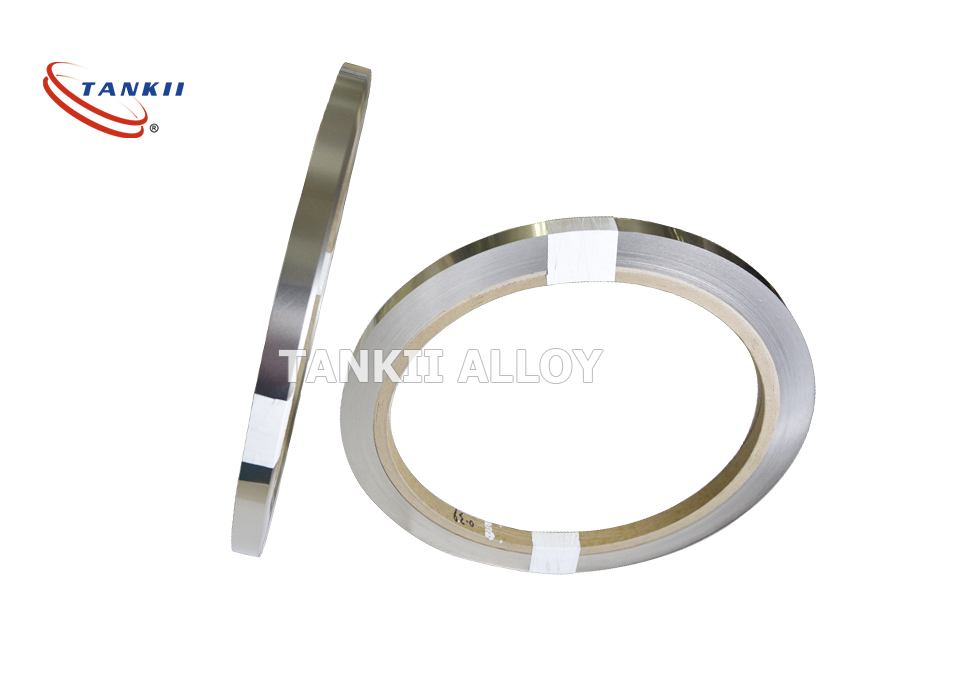

FeCrAl AlloyFoil/Trip Coil 0.05mm Kauri don Ƙarfe na Ƙarfe na zuma

Babban abun ciki na aluminum, a hade tare da babban abun ciki na chromium yana haifar da yawan zafin jiki don ƙarawa har zuwa 1425 C (2600F);Karkashin kanun labarai juriya zafi, wadannanFeCrAl alloyAna kwatanta s tare da abubuwan da aka saba amfani da su na Fe da Ni.Kamar yadda ake iya gani daga wannan tebur, daFeCrAl alloys suna da kyawawan kaddarorin idan aka kwatanta da sauran gami a mafi yawan mahalli.

Ya kamata a lura da cewa, a lokacin yanayin yanayin zafi daban-daban, yttrium ƙari ga AF alloy wanda kuma aka sani da Fecralloys alloys, yana inganta riko da oxide mai karewa, yana sa rayuwar sabis na abubuwan da ke cikin AF alloy ya fi tsayi fiye da na darajar A-1.

Fe-Cr-Al alloy wayoyi an yi su ne da ƙarfe chromium aluminum base alloys dauke da ƙananan abubuwa masu amsawa kamar yttrium da zirconium kuma ana samar da su ta hanyar narkewa, jujjuyawar ƙarfe, ƙirƙira, cirewa, zane, jiyya na ƙasa, gwajin sarrafa juriya, da sauransu.

Fe-Cr-Al waya aka tsara ta hanyar high gudun atomatik sanyaya inji wanda ikon ikon sarrafa ta kwamfuta, suna samuwa a matsayin waya da ribbon (strip).

Features da abũbuwan amfãni

1. Babban amfani da zafin jiki, matsakaicin amfani da zafin jiki zai iya kaiwa 1400C (0Cr21A16Nb, 0Cr27A17Mo2, da dai sauransu)

2. Low zazzabi coefficient na juriya

3. Ƙarƙashin haɓaka haɓakar haɓakar thermal fiye da Ni-base super-alloys.

4. High resistivity lantarki

5. Kyakkyawan juriya na lalata a ƙarƙashin yanayin zafi, musamman a ƙarƙashin yanayin da ke dauke da sulfide

6. High surface load

7. Mai juriya

8. Ƙananan farashin kayan abu, Ƙananan yawa da farashi mai rahusa idan aka kwatanta da waya Nichrome.

9. Mafi girman juriya na iskar shaka a 800-1300ºC

10. Rayuwa mai tsawo

Samuwar matakan alumina da ake iya daidaitawa saboda iskar shaka na kasuwanciFeCrAl alloyan yi nazarin wayoyi (kauri 0.5 mm) a yanayi daban-daban da lokutan lokaci.Samfurori sun kasance iskar oxygen a cikin iska ta amfani da mai nazarin thermogravimetric (TGA).An yi nazarin ilimin halittar ɗan adam na samfuran oxidised ta amfani da Microscope Electron Scanning Electron (ESEM) da kuma X-ray akan binciken saman da aka yi ta amfani da na'urar nazarin makamashi Dispersive X-Ray (EDX).An yi amfani da fasaha na X-Ray Diffraction (XRD) don kwatanta lokacin girma na oxide.Duk binciken ya nuna cewa yana yiwuwa a shuka gamma alumina mai tsayi a samanFeCrAl alloysaman waya lokacin da isothermally oxidised sama da 800 ° C a cikin da yawa hours.

| Iron Chrome Aluminum | |||||||

| OCr25Al5 | CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| Saukewa: OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Iron Chrome Aluminum | ||

| OCr25Al5 | Ana iya amfani da shi a yanayin aiki har zuwa 1350 ° C, kodayake yana iya zama ƙwanƙwasa. | Abubuwan dumama na tanderun zafin jiki da dumama dumama. |

| OCr20Al5 | Ferromagnetic gami wanda za'a iya amfani dashi a yanayin zafi har zuwa 1300 ° C.Ya kamata a yi amfani da shi a cikin busassun wurare don guje wa lalata.Za a iya yin ɓarna a babban yanayin zafi. | Abubuwan dumama na tanderun zafin jiki da dumama dumama. |