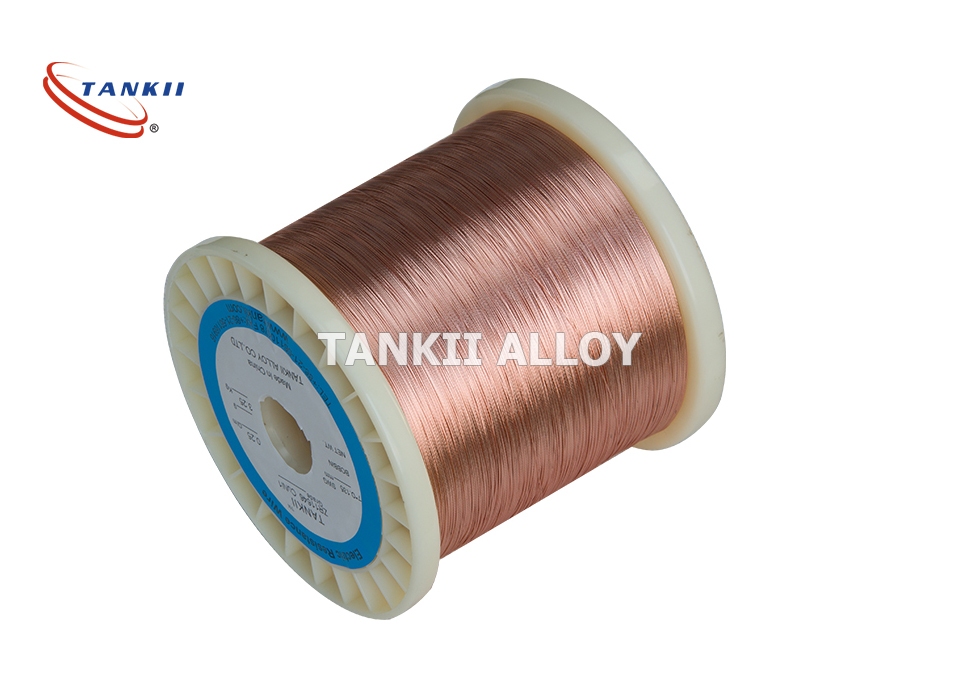

Wayar Juriya ta Alloy 180 Manganin Mai Rufewa da Tagulla Nickel CuNi

Nicr Mai Zagaye Bisa TagullaGami 180Wayar Copper Mai Rufi ...

1. Bayanin Kayan Aiki Gabaɗaya

1)

Manganinyawanci ƙarfe ne mai kashi 84% na jan ƙarfe, 12% na manganese, da kuma 4% na nickel.

Ana amfani da wayar Manganin da foil wajen kera resistors, musamman ammeter shunt, saboda kusan sifili ne na juriya da kuma kwanciyar hankali na dogon lokaci. Da yawa daga cikin resistors na Manganin sun yi aiki a matsayin mizani na doka don ohm a Amurka daga 1901 zuwa 1990. Haka kuma ana amfani da wayar Manganin a matsayin mai sarrafa wutar lantarki a cikin tsarin cryogenic, yana rage canja wurin zafi tsakanin wuraren da ke buƙatar haɗin lantarki.

Ana kuma amfani da Manganin a cikin ma'aunin aunawa don nazarin raƙuman girgiza masu ƙarfi (kamar waɗanda aka samar daga fashewar abubuwan fashewa) saboda yana da ƙarancin ƙarfin juriya ga damuwa amma yana da ƙarfin juriya ga matsin lamba na hydrostatic.

2)

Constantanwani ƙarfe ne na jan ƙarfe-nickel wanda aka fi sani daEureka, Ci gaba, kumaJirgin ruwaYawanci yana ƙunshe da kashi 55% na jan ƙarfe da kashi 45% na nickel. Babban fasalinsa shine juriyarsa, wanda yake dawwama a cikin yanayi daban-daban na yanayin zafi. An san wasu ƙarfe masu ƙarancin zafin jiki iri ɗaya, kamar manganin (Cu)86Mn12Ni2).

Don auna manyan nau'ikan, 5% (microstrian 50,000) ko sama da haka, annealed constantan (P alloy) shine kayan grid da aka saba zaba. Constantan a cikin wannan nau'in yana da ƙarfi sosai; kuma, a cikin tsawon ma'auni na inci 0.125 (3.2 mm) ko fiye, ana iya tarawa zuwa >20%. Duk da haka, ya kamata a tuna cewa a ƙarƙashin manyan nau'ikan cyclic alloy na P zai nuna wani canjin juriya na dindindin tare da kowane zagaye, kuma yana haifar da canjin sifili daidai a cikin ma'aunin strength. Saboda wannan halayyar, da kuma yanayin gazawar grid da wuri tare da maimaita matsewa, ba a ba da shawarar P alloy don aikace-aikacen cyclic strength ba. Ana samun P alloy tare da lambobin STC na 08 da 40 don amfani akan karafa da robobi, bi da bi.

2. Gabatarwa da aikace-aikacen Waya Mai Lamba

Ko da yake an bayyana wayar da aka yi da "enameled", a zahiri ba a shafa mata fenti ko dai da fenti mai kama da enamel ko kuma da vitreous enamel da aka yi da foda gilashi mai haɗe. Wayar maganadisu ta zamani yawanci tana amfani da yadudduka ɗaya zuwa huɗu (idan akwai waya mai siffar quad-film) na rufin fim ɗin polymer, galibi na abubuwa biyu daban-daban, don samar da Layer mai tauri da ci gaba da rufewa. Fina-finan toshe waya na maganadisu suna amfani da (domin ƙara yawan zafin jiki) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (ko amide-imide), da polyimide. Wayar maganadisu mai kauri ta Polyimide tana iya aiki har zuwa 250 °C. Sau da yawa ana ƙara rufin waya mai kauri murabba'i ko murabba'i ta hanyar naɗe shi da tef ɗin polyimide ko fiberglass mai zafi, kuma an cika windings ɗin da fenti mai kauri da varnish mai rufewa don inganta ƙarfin rufi da amincin na'urar naɗewa na dogon lokaci.

Ana ɗaure na'urorin da ke ɗaukar kansu da waya da aka lulluɓe da aƙalla layuka biyu, mafi bayansu shine thermoplastic wanda ke haɗa juyawar tare lokacin da aka dumama.

Ana kuma amfani da wasu nau'ikan rufin kamar zaren fiberglass mai varnish, takardar aramid, takardar kraft, mica, da fim ɗin polyester a ko'ina cikin duniya don aikace-aikace daban-daban kamar transformers da reactors. A ɓangaren sauti, ana iya samun waya ta ƙarfe, da sauran abubuwan hana ruwa, kamar auduga (wani lokacin ana cika ta da wani nau'in abin hana ruwa/mai kauri, kamar kakin zuma) da polytetrafluoroethylene (PTFE). Tsoffin kayan hana ruwa sun haɗa da auduga, takarda, ko siliki, amma waɗannan suna da amfani ne kawai don aikace-aikacen ƙarancin zafin jiki (har zuwa 105°C).

Domin sauƙin ƙera wasu igiyoyin maganadisu masu ƙarancin zafin jiki, suna da rufin da za a iya cirewa ta hanyar zafin haɗakarwa. Wannan yana nufin cewa ana iya yin haɗin lantarki a ƙarshen ba tare da cire rufin ba tukuna.

3. Sinadaran Sinadarai da Babban Kayan Aiki na Alloy Mai Ƙarfin Juriya na Cu-Ni

| PropertiesGrade | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Babban Sinadarin Sinadarai | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Matsakaicin Zafin Aiki Mai Ci Gaba (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Juriya a 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Yawan yawa (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Tsarin isar da zafi (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Ƙarfin Tashin Hankali (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Kimanin Ma'aunin Narkewa (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Tsarin Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Kadarar Magnetic | ba | ba | ba | ba | ba | ba | |

| PropertiesGrade | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Babban Sinadarin Sinadarai | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Matsakaicin Zafin Aiki Mai Ci Gaba (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Juriya a 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Yawan yawa (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Tsarin isar da zafi (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Ƙarfin Tashin Hankali (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Kimanin Ma'aunin Narkewa (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Tsarin Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Kadarar Magnetic | ba | ba | ba | ba | ba | ba | |

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama