Barka da zuwa gidajen yanar gizon mu!

Tankii S-Type Thermocouple Sensor Girman Zafin Masana'antu da Daidaito

Bayanin Samfurin

Firikwensin Thermocouple na S-Nau'in S (0-1300℃, Tsawon 250mm)

Bayanin Samfuri

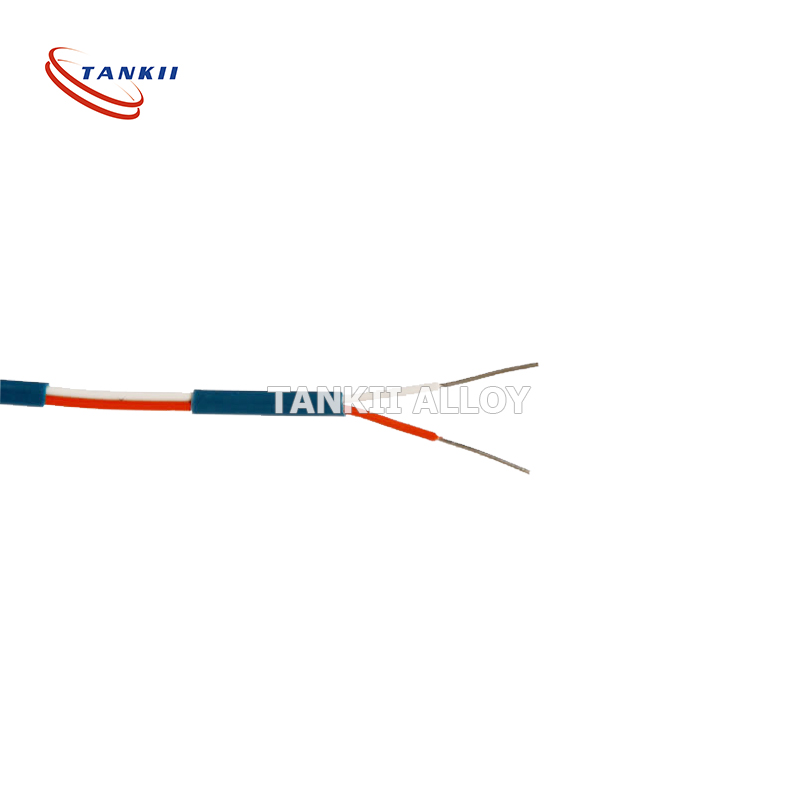

Na'urar firikwensin thermocouple ta S-type (platinum-rhodium 10%-platinum, Pt10Rh/Pt) daga Tankii Alloy Material wani sinadari ne mai auna zafin jiki mai inganci wanda aka ƙera don yanayin zafi mai tsanani. Tare da ƙirar da aka ƙera ta tsawon 250mm, bututun kariya na yumbu mai diamita 7-8mm, da kuma waya mai auna diamita 0.2mm, wannan na'urar firikwensin tana samun ingantaccen gano zafin jiki a fadin 0-1300℃ ta hanyar tasirin Seebeck na ƙarfe mai daraja. Yana haɗawakyakkyawan kwanciyar hankali mai zafi,ƙarancin ma'auni na girgiza, kumaƙarfi mai ƙarfi na tsarin— wanda hakan ya sa ya zama zaɓi mafi dacewa ga hanyoyin zafi mai yawa kamar sa ido kan zafin tanderun masana'antu, tantance yanayin zafi na maganin zafi, da kuma gwajin ingancin kayan lantarki mai zafi mai yawa.

Tsarin Ma'auni da Gidauniyar Tsarin

- Na'urar auna firikwensin: Nau'in S (IEC 60584-1 Class 1; daidai da ANSI/ASTM E230 Type S) - thermocouple na ƙarfe mai daraja tare da Pt10Rh (possible electrode) da kuma masu sarrafa Pt (negative electrode) masu tsabta

- Bayani dalla-dalla: Yankin zafin jiki 0-1300℃ (amfani na ɗan gajeren lokaci har zuwa 1400℃ na ≤30min); jimlar tsawon 250mm (auna tsawon ƙarshen 50mm, tsawon wayar gubar 200mm); diamita na waje na bututun kariya na yumbu 7-8mm (kauri bango 1.2-1.5mm); diamita na waya mai jagora 0.2mm (juriya ±0.01mm)

- Ka'idojin da suka dace: IEC 60584-1 (aji na daidaiton thermocouple), GB/T 1672-1997 (ma'aunin thermocouples na platinum-rhodium), ASTM E230-19 (ma'aunin thermocouples na ƙarfe mai daraja)

- Mai ƙera: Tankii Alloy Material, wanda aka ba da takardar shaida bisa ga ISO 9001 da ISO 14001, tare da narkar da ƙarfe mai daraja da kuma ƙarfin daidaita firikwensin a cikin gida

Babban Amfanin (An daidaita shi don 0-1300℃ & Bayanin Tsarin)

1. Daidaito da Daidaiton Ma'aunin Zafi Mai Girma

Yana ɗaukar waya mai ƙarfi ta Pt10Rh/Pt mai tsafta 99.99% (diamita 0.2mm) tare da haɗin ƙarfe iri ɗaya - daidaiton aunawa ya kai ga Aji na 1 (kuskure ≤±1.5℃ a 0-600℃, ≤±0.25% t a 600-1300℃, t=zafin da aka auna). Bayan sa'o'i 1000 na ci gaba da aiki a 1200℃, yuwuwar juyawar thermoelectric shine <3μV (daidai yake da kuskuren zafin jiki <0.4℃) - ya fi na'urorin thermocouples na nau'in K (digital >10μV a 800℃) kuma ya dace da sa ido kan zafin jiki na dogon lokaci.

2. Ingantaccen Tsarin Dorewa

- Tube Kariyar Yumbu: diamita na waje mai girman alumina mai girman 7-8mm (Abubuwan da ke cikin Al₂O₃ ≥95%) tare da juriya mai zafi har zuwa 1600℃, ƙarfin matsi ≥150MPa—yana ware ƙarfe mai narkewa, ƙurar tanderu, da iskar gas mai lalata yadda ya kamata yayin da yake tabbatar da ingancin canja wurin zafi (ƙarfin wutar lantarki ≥20 W/(m·K) a 800℃).

- Tsarin Jagora da Haɗi: Mai sarrafa diamita 0.2mm yana daidaita sassauci da ƙarfin zafin jiki mai yawa (ƙarfin tauri ≥350MPa a 25℃, ≥150MPa a 1300℃); ƙarshen aunawa yana ɗaukar walda tabo (diamita na walda tabo 0.3-0.4mm) don tabbatar da ingantaccen fitarwa mai amfani da zafi ba tare da juriya ga hulɗa ba.

- Daidaita Jimlar Tsawon: Jimlar tsawon mm 250 (ƙarshen aunawa na mm 50 + wayar gubar mm 200) an inganta ta don shigar da bangon gefe na tanderun masana'antu - yana guje wa lanƙwasa waya mai gubar da yawa yayin da yake tabbatar da cewa ƙarshen aunawa ya kai ga yankin zafin jiki na tsakiya.

3. Amintaccen Aiki Mai Daidaita

Na'urar firikwensin tana da juriyar iskar shaka (tana samar da fim mai kauri na kariya daga iskar shaka (PtO₂) da kuma juriyar girgizar zafi (tana iya jure canjin zafin jiki na 500℃/min ba tare da fashewar bututun yumbu ba). Wayar jagora tana amfani da rufin Teflon mai zafi (zafin aiki -60℃ zuwa 260℃) don hana gajerun da'irori a wuraren bita na zafi mai zafi, kuma tashar tana da mahaɗin M12 na yau da kullun don haɗawa cikin sauri zuwa masu watsa zafin jiki.

Bayanan Fasaha

| Siffa | Darajar (Na yau da kullun) | Muhimmancin Aikace-aikace |

|---|---|---|

| Nau'in Na'urar Firikwensin | Nau'in S (Pt10Rh/Pt) | Babban tsarkin ƙarfe mai daraja yana tabbatar da kwanciyar hankali mai zafi |

| Yanayin Zafin Jiki | 0-1300℃ (ci gaba); 0-1400℃ (na ɗan gajeren lokaci ≤30min) | Ya ƙunshi yawancin hanyoyin da ake amfani da su a yanayin zafi mai yawa a masana'antu |

| Daidaiton Ma'auni | Aji na 1: ±1.5℃ (0-600℃); ±0.25% t (600-1300℃) | Ya cika buƙatun gyaran zafi daidai (misali, kashe sassan mota) |

| Jimlar Tsawon | 250mm (An ƙayyade) | An inganta shi don shigarwa na bangon gefe na tanda |

| Bayanin Bututun Yumbu | Diamita na waje 7-8mm | Daidaita kariyar da ingancin canja wurin zafi |

| Diamita na Wayar Jagora | 0.2mm (juriya ±0.01mm) | Yana tabbatar da kwanciyar hankali da sassaucin yanayin zafi |

| Ƙarfin Wutar Lantarki (1000℃) | 10.591mV (idan aka kwatanta da 0℃ mahaɗin ma'auni) | Ya yi daidai da ƙimar daidaitawa ta IEC 60584-1 |

| Lokacin Amsawa (τ₅₀) | ≤2s (a cikin iska a 800℃) | Yana daidaitawa da canje-canjen zafin jiki masu canzawa a cikin maganin zafi |

| Rayuwar Sabis (1200℃ ci gaba) | ≥Awowi 1000 | Rage yawan kulawa ga tanderun masana'antu |

Bayanin Samfura

| Abu | Ƙayyadewa | Amfanin Aiki |

|---|---|---|

| Kariya Tube Material | 95% na yumbu mai yawan aluminum | Juriyar zafin jiki mai yawa da juriyar tsatsa |

| Rufin Mai Gudanarwa | Babban tsarkin alumina mai yumbu (sashe 250℃); Teflon (sashen zafin ɗaki) | Yana hana gajeren da'ira a yanayin zafi mai yawa |

| Mai Haɗa Tashar | Mai haɗa ruwa mai hana ruwa M12 (matakin kariyar IP65) | Shigarwa da sauri & kura/mai hana ruwa |

| Takardar Shaidar Daidaitawa | Rahoton daidaitawa wanda za a iya bibiyarsa ta NIST (zaɓi ne) | Ya cika buƙatun tabbatar da ilimin metrology |

| Marufi | Kumfa mai hana girgiza da akwatin kwali; marufi mai sassa ɗaya | Yana hana karyewar bututun yumbu yayin jigilar kaya |

| Keɓancewa | Jimlar tsawon (100-1000mm); kayan bututun yumbu (99% alumina na 1600℃); nau'in mahaɗi (ƙaramin mahaɗi don na'urorin lantarki) | Ya dace da buƙatun shigarwa da aikace-aikace na musamman |

Yanayin Aikace-aikace na yau da kullun

1. Tsarin Zafin Jiki Mai Tsayi na Masana'antu

Ana amfani da shi don sa ido kan zafin jiki a cikin tanderun sarrafa zafi na ƙarfe (misali, annealing na bakin ƙarfe a 900-1100℃) da kuma murhun sintering na yumbu (1200-1300℃)—bututun yumbu mai tsawon mm 7-8 yana hana yashewar ƙurar tanderu, kuma daidaiton aji na 1 yana tabbatar da ingancin samfur mai daidaito.

2. Gwajin Ingancin Kayan Lantarki

Ana amfani da shi a gwaje-gwajen tsufa masu zafi na guntu-guntu na semiconductor da na'urorin wutar lantarki (0-1200℃) - mai sarrafa sirara mai girman 0.2mm da lokacin amsawa mai sauri (≤2s) daidai yake da canjin zafin jiki na ɗan lokaci yayin dumama sassan, yana ba da tallafin bayanai don kimanta aminci.

3. Na'urar auna matsin lamba mai yawan zafin jiki

A matsayin ma'aunin zafin jiki a cikin tsarin daidaita zafin jiki mai zafi mai yawa (misali, daidaita na'urori masu auna matsin lamba na injin mota a 800-1000℃) - fitowar ƙarfin thermoelectric mai ƙarfi yana tabbatar da daidaiton daidaitawa na na'urori masu auna matsin lamba.

4. Binciken Zafin Jiki Mai Tsanani a Dakunan Gwaji

Ana amfani da shi a dakunan gwaje-gwajen kimiyyar kayan aiki don gwajin canjin yanayi mai zafi (0-1300℃) - tsayin 250mm ya dace da tanderun benci, kuma zaɓin daidaitawar NIST ya cika buƙatun binciken bayanai.

Tabbatar da Inganci da Tallafin Fasaha

Tankii Alloy Material yana aiwatar da sarrafa inganci na matakai uku don na'urori masu auna zafin jiki na S-type:

- Duba Mai Gudanarwa: Binciken abubuwan da aka haɗa na ƙarfe na XRF (yana tabbatar da abun ciki na Pt10Rh 9.5-10.5%) da gwajin juriya na maki huɗu (yana tabbatar da tsarki).

- Gwajin Haɗawa: Daidaita zafin jiki mai yawa a cikin tanda mai daidaito (daidaitaccen zafin jiki ±0.1℃) da gwajin girgizar zafi (zagaye 50 na 25℃-1300℃).

- Tabbatarwa ta ƘarsheGwajin aiki na tsawon awanni 24 a 1200℃ don tabbatar da aikin karkatarwa da gwajin hana ruwa haɗawa (IP65).

Ana samun samfura kyauta (tare da rahoton daidaitawa) da jagorar shigarwa a wurin idan an buƙata. Ƙungiyarmu ta fasaha tana ba da mafita na musamman kamar inganta tsawon firikwensin don murhu na musamman da kuma jagorar daidaitawa tare da masu watsa zafin jiki don tabbatar da ingantaccen aikin aunawa.

Rubuta saƙonka a nan ka aika mana da shi

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama