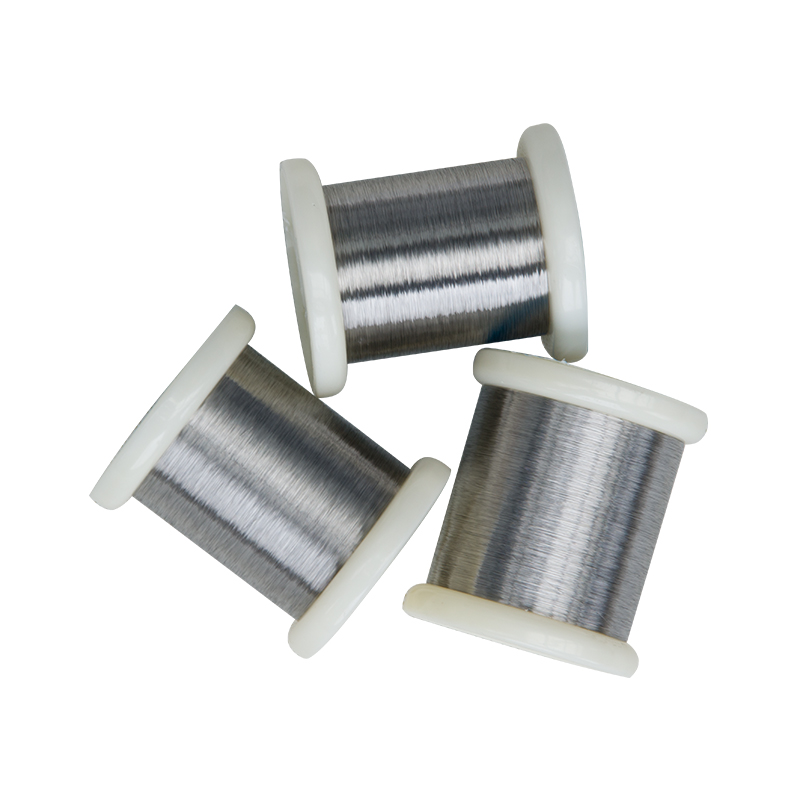

Tsarkakken Nickel 200/Uns Waya 2200 0.25mm

Tsarkakken Nickel 200/Uns Waya 2200 0.25mm

Ma'auni:Ni200,Ni201,N4,N6

Babban sassauci

Kyakkyawan juriya ga lalata

ƙarfin injina mai kyau

Bayanin Gami

Nickel 200/201 shine nau'in da aka fi amfani da shi, wanda aka ƙayyade shi gabaɗaya don murfi na transistor, anode na bututun lantarki, leads na kayan lantarki / Lead-in-Wires don fitilu da kuma Wire-Mesh. Hakanan ana amfani da shi a cikin nau'in tsiri don aikace-aikace daban-daban ciki har da batirin Ni-Cd.

Yanayin Samarwa

Ana samar da Nickel 200, 201 da 205 a cikin waɗannan yanayi:

Sanyi, Fushi na Musamman.

An yi masa fenti mai sanyi, an yi masa fenti mai laushi. An miƙe kuma an yanke tsawonsa.

Lura:

NUS N02201 (ASTM B 162) iri ɗaya da N4 (GB/T 2054).

NUS N02200 (ASTM B 162) iri ɗaya da N6 (GB/T 2054).

Siffofin

Nada - Zare, Foil, Ribbon

Waya - Bayanin Yanayi, Zagaye, Lebur, Murabba'i

sanda, sanda, kayan ado, faranti, takarda

Sinadarin sinadarai

| Matsayi | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

| N4 | 99.9 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 |

| N6 | 99.6 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

| Ni201 | 99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

| Ni200 | 99.0 | 0.20 | 0.30 | 0.30 | 0.15 | / | 0.01 | / | 0.40 |

![]()

![]()

![]()

![]()

Ƙarfin Nickel

| Matsayi | Tsabtataccen Nickel Zirin 99.6% / 99.9% |

| Kauri | 0.002 zuwa 2.50 mm |

| Juriya | +/- 5% (ana samun haƙuri na musamman) |

| Faɗi | Har zuwa faɗin mm 350 |

| Girman nada | Har zuwa kilogiram 80 ba tare da walda ba |

| Yanayin Zafi | An haɗa shi zuwa Cikakken Hard |

![]()

![]()

![]()

![]()

Daidaiton Samfurin Nickel Foil

| Kauri | Kauri izinin | Burr tsayi | Faɗin faɗi da haƙuri | |||||

| 2≤w <10 | 10≤w <50 | 50≤w <100 | 100≤w <150 | 150≤w <200 | 200≤w | |||

| 0.02≤t <0.05 | ±0.003 | ≤0.005 | ± 0.05 | ±0.10 | ±0.15 | ±0.20 | ±0.30 | ±0.50 |

| 0.05≤t <0.1 | ±0.005 | ≤0.01 | ||||||

| 0.1≤t <0.2 | ±0.008 | ≤0.015 | ||||||

| 0.2≤t <0.3 | ±0.012 | ≤0.02 | ||||||

| 0.3≤t <0.4 | ±0.015 | ≤0.03 | ± 0.10 | ±015 | ±0.25 | ±0.50 | ±0.80 | ±1.00 |

| 0.4≤t <0.6 | ±0.025 | ≤0.05 | ||||||

| 0.6≤t <0.8 | ±0.030 | ≤0.06 | ± 0.30 | ±0.40 | ±0.50 | ±0.50 | ±0.80 | ±1.00 |

| 0.8≤t <1.0 | ±0.040 | |||||||

| 1.0≤t <1.2 | ±0.050 | ≤0.08 | ± 0.50 | ±0.50 | ±0.80 | ±1.00 | ±1.00 | ±1.50 |

| 1.2≤t <1.4 | ±0.060 | |||||||

| 1.4≤t <1.7 | ±0.070 | ≤0.10 | ||||||

| 1.7≤t <2.0 | ±0.080 | |||||||

![]()

![]()

![]()

![]()

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama