Wayar Alloy ta Masana'antu Kai Tsaye 4j52 / NiFe52 / Fadadawa / Daidaito

Alloy 52 Ya ƙunshi kashi 52% na nickel da kashi 48% na baƙin ƙarfe kuma ana amfani da shi sosai a masana'antar sadarwa. Hakanan yana samun aikace-aikace a cikin nau'ikan aikace-aikacen lantarki iri-iri, musamman don hatimin gilashi.

Alloy 52 yana ɗaya daga cikin ƙarfen da aka yi amfani da shi wajen rufe gilashi zuwa ƙarfe wanda aka ƙera don amfani da shi tare da nau'ikan tabarau masu laushi. An san shi da yawan faɗaɗa zafi wanda kusan yake daidai har zuwa 1050F (565C).

Girman Girma:

*Takarda—Kauri 0.1mm~40.0mm, faɗi:≤300mm, Yanayi: an yi birgima da sanyi (zafi), mai haske, mai haske a rufe

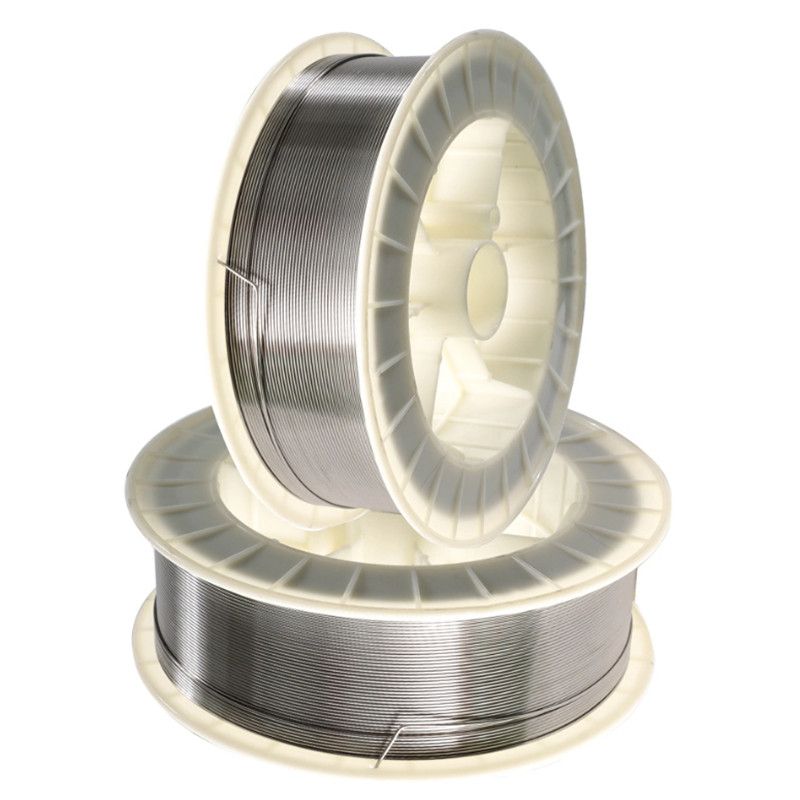

*Wayar Zagaye—Dia 0.1mm~Dia 5.0mm,Yanayi: an ja shi da sanyi, mai haske, mai haske a rufe

*Wayar lebur—Dia 0.5mm~Dia 5.0mm, tsayi: ≤1000mm, Yanayi: an yi birgima a lebur, an yi masa fenti mai haske

*Mashaya—Dia 5.0mm~Dia 8.0mm, tsayi: ≤2000mm, Yanayi: an ja shi da sanyi, mai haske, mai haske a rufe

Dia 8.0mm~Dia 32.0mm, tsayi: ≤2500mm, Yanayi: an yi birgima da zafi, mai haske, mai haske a rufe

Dia 32.0mm~ Dia 180.0mm, tsayi: ≤1300mm, Yanayi: ƙera mai zafi, bare, juya, an yi masa magani da zafi

*Kapilari—OD 8.0mm~1.0mm, ID 0.1mm~8.0mm, tsayi:≤2500mm, Yanayi: an yi masa fenti mai sanyi, mai haske, mai haske.

*Bututu—OD 120mm~8.0mm, ID 8.0mm~129mm, tsayi:≤4000mm, Yanayi: an yi masa fenti mai sanyi, mai haske, mai haske.

Sinadaran Kimiyya:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Minti | – | – | – | – | – | – | – | – | 50.5 | – |

| Mafi girma | 0.25 | 0.10 | 0.05 | Bal. | 0.60 | 0.30 | 0.025 | 0.025 | – | 0.5 |

Matsakaicin Ma'aunin Faɗaɗawa Mai Layi:

| Matsayi | α1/10-6ºC-1 | |||||||

| 20~100ºC | 20~200ºC | 20~300ºC | 20~350ºC | 20~400ºC | 20~450ºC | 20~500ºC | 20~600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

Kadarorin:

| Yanayi | Kimanin ƙarfin tensile | Kimanin zafin aiki | ||

| N/mm² | ksi | °C | °F | |

| An rufe | 450 – 550 | 65 – 80 | har zuwa +450 | har zuwa +840 |

| An zana da ƙarfi | 700 – 900 | 102 – 131 | har zuwa +450 | har zuwa +840 |

| Ƙirƙira: |

| Gilashin yana da kyakkyawan ductility kuma ana iya ƙirƙirar shi ta hanyar amfani da hanyoyin da aka saba. |

| Walda: |

| Walda ta hanyar hanyoyin gargajiya ya dace da wannan ƙarfe. |

| Maganin Zafi: |

| Ya kamata a yi amfani da na'urar Alloy 52 a zafin jiki na 1500F sannan a sanyaya iska. Ana iya rage matsin lamba a matsakaicin zafin jiki na 1000F. |

| Ƙirƙira: |

| Ya kamata a yi amfani da injin a zafin jiki na 2150 F. |

| Aiki a Sanyi: |

| Ana iya amfani da ƙarfe cikin sanyi. Ya kamata a ƙayyade ƙimar zane mai zurfi don wannan aikin ƙira da kuma ƙimar annealed don ƙirƙirar gabaɗaya. |

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama