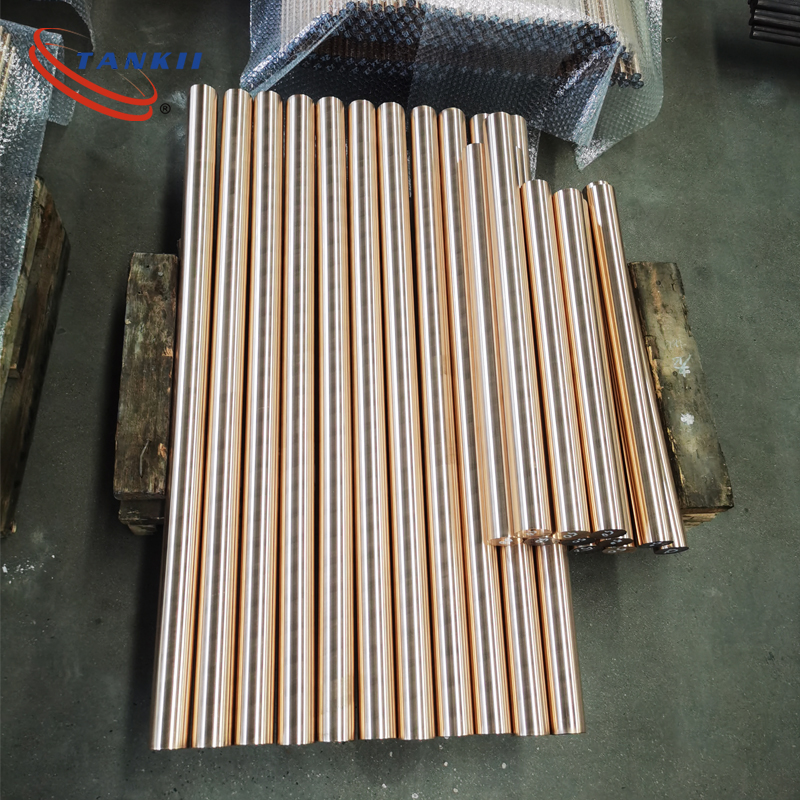

Wayoyin Inconel 625 718 600 Wayoyi N06625 Masu Kyau/Mai Cika/Walda

Inconel wani iyali ne na ƙarfe mai ƙarfi wanda aka yi da nickel chromium na austenitic.

Gilashin Inconel kayan kariya ne daga iskar shaka da kuma iskar shaka, waɗanda suka dace da aiki a cikin mawuyacin yanayi waɗanda ke fuskantar matsin lamba da kuma

zafi. Idan aka yi zafi, Inconel yana samar da wani Layer mai kauri, mai karko, mai saurin rufewa wanda ke kare saman daga ƙarin hari. Inconel yana riƙewa

ƙarfi akan kewayon zafin jiki mai faɗi, mai kyau ga aikace-aikacen zafin jiki mai yawa inda aluminum da ƙarfe zasu iya jure wa ƙwanƙwasawa

sakamakon gurɓatattun wurare da aka haifar da lu'ulu'u ta hanyar zafi. Ƙarfin zafin Inconel mai yawa yana tasowa ta hanyar maganin ƙarfi

ƙarfafawa ko taurarewar hazo, ya danganta da ƙarfe.

Inconel 718 wani ƙarfe ne na nickel-chromium-molybdenum wanda aka ƙera don jure wa yanayi mai yawa na lalata, tsatsa da kuma tsatsa a cikin rami. Wannan ƙarfe na nickel kuma yana nuna halayen yawan amfanin ƙasa, tensile, da kuma fashewar abubuwa a yanayin zafi mai yawa. Ana amfani da wannan ƙarfe na nickel daga yanayin zafi mai ƙarfi har zuwa aiki na dogon lokaci a 1200° F. Ɗaya daga cikin abubuwan da suka bambanta na abun da ke cikin Inconel 718's shine ƙara niobium don ba da damar taurarewa na tsufa wanda ke ba da damar annealing da walda ba tare da taurarewa ba a lokacin dumama da sanyaya. Ƙara niobium yana aiki tare da molybdenum don taurare matrix na ƙarfe kuma yana ba da ƙarfi mai yawa ba tare da maganin zafi mai ƙarfi ba. Sauran shahararrun ƙarfe na nickel-chromium ana ƙera su cikin sauƙi kuma ana iya walda su a cikin yanayin annealed ko hazo (shekaru). Ana amfani da wannan ƙarfe mai ƙarfi a cikin masana'antu daban-daban kamar su sararin samaniya, sarrafa sinadarai, injiniyan ruwa, kayan aikin sarrafa gurɓataccen iska, da masu samar da makamashin nukiliya.

Abubuwan da ke da zafi mai yawa, kamar ruwan turbine, vanes na jagora, faifan turbine, faifan matsewa mai ƙarfi, ɗakunan kera injina da na ƙonewa da ake amfani da su wajen ƙera turbines na jiragen sama, na ruwa da na masana'antu.

| Abu | Inconel 600 | Inconel | Inconel 617 | Inconel | Inconel | Inconel | Inconel | |

| 601 | 690 | 718 | X750 | 825 | ||||

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6~10 | hutawa | ≤3 | hutawa | 7~11 | hutawa | 5~9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | – | – | – | – | – |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | – | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥7.2 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | – | – | 10~15 | ≤10 | – | ≤1 | ≤1 | – |

| Al | – | 1-1.7 | 0.8-1.5 | ≤0.8 | – | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | – | – | ≤0.6 | ≤1.15 | – | – | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | – | – | – | 4.75-5.5 | – | 4.75-5.5 | 0.7-1.2 | – |

| Mo | – | – | 8~10 | 2.8-3.3 | – | 2.8-3.3 | – | 2.5-3.5 |

| B | – | – | ≤0.006 | – | – | – | – | – |

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama