Barka da zuwa gidajen yanar gizon mu!

Ana Haja Mai Inganci Mai Kyau ТБ2013/TM-2/108SP Bimetallic Strip don Kula da Temporary Control

Bayanin Samfurin

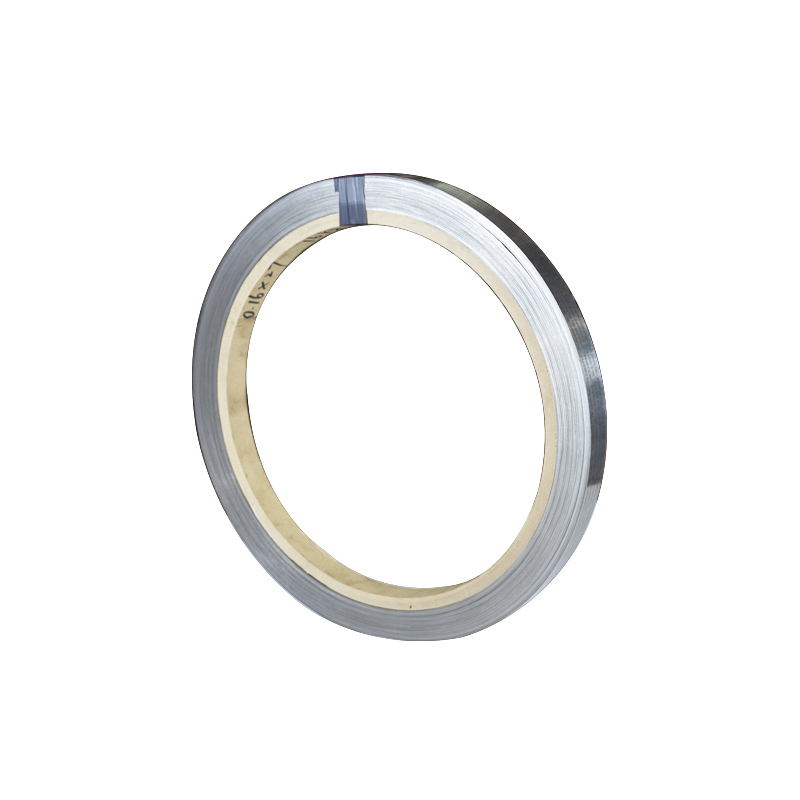

ТБ2013/TM-2/108SP Bimetallic Strip

Bayanin Samfuri

ТБ2013/TM-2/108SP bimetallic strip, wani babban kayan aiki mai aiki wanda Tankii Alloy Material ya ƙirƙira kuma ya ƙera, wani nau'i ne na musamman da aka inganta don yanayin yanayin zafi mai matsakaici zuwa babban zafin jiki. An haɗa shi da ƙarfe biyu daban-daban tare da daidaitattun ma'aunin faɗaɗa zafi - waɗanda aka haɗa ta hanyar fasahar watsa zafi ta Huona - wannan tsiri yana haɗa manyan fa'idodi guda uku: amsawar zafin jiki mai ɗorewa, kyakkyawan juriya ga gajiya ta injiniya, da kuma daidaitawa mai faɗi na muhalli. Ba kamar tsiri biyu na bimetallic ba, an ƙera matakin ТБ2013/TM-2/108SP don daidaita yanayin zafi da ƙarfin tsari, wanda hakan ya sa ya dace da na'urorin dumama na masana'antu, masu kare zafi fiye da kima na mota, da kuma abubuwan da suka dace da yanayin zafi a cikin mawuyacin yanayi (misali, zafi mai yawa, girgiza).

Tsarin Ma'auni da Tsarin Mahimmanci

- Matsayin Samfuri: ТБ2013/TM-2/108SP

- Tsarin Haɗaɗɗen Siffa: Yawanci ya ƙunshi "layin faɗaɗawa mai yawa" da "layin faɗaɗawa mai ƙarancin girma"; ƙarfin haɗin fuska ≥140 MPa

- Ka'idojin da suka dace: Yana bin GOST 28561-90 (ma'aunin Rasha don tsiri na bimetallic) da IEC 60694 don abubuwan sarrafa zafi; sun dace da buƙatun EU RoHS

- Mai ƙera: Tankii Alloy Material, wanda aka ba da takardar shaida ga ISO 9001 da ISO 14001, tare da tsarin ƙarfe na cikin gida da kuma damar haɗakar kayan haɗin kai don dacewa da takamaiman buƙatun aiki na matakin.

Manyan Fa'idodi (idan aka kwatanta da Rigunan Bimetallic na Janar)

ТБ2013/TM-2/108SP ya shahara saboda aikin sa na mayar da hankali kan aikace-aikace, yana magance matsalolin da ke tattare da amfani da masana'antu da muhalli mai tsauri:

- Damar Zafin Jiki Mai Faɗi: Yana aiki cikin kwanciyar hankali a cikin -50℃ zuwa 250℃ (ci gaba da amfani), tare da juriya na ɗan gajeren lokaci har zuwa 300℃—wanda ya fi daidaitattun sandunan bimetallic (an iyakance shi zuwa ≤200℃) kuma ya dace da yanayin masana'antu masu zafi sosai (misali, na'urori masu auna sassan injin).

- Ƙarancin Hawan Jini na Zafi: Kuskuren Hawan Jini ≤3℃ (tsakanin wuraren kunna dumama da sanyaya) a 150℃—yana da mahimmanci don daidaita yanayin zafi (misali, na'urorin dumama tanda na masana'antu) inda zagayowar kunnawa/kashewa da aka maimaita ke buƙatar daidaitattun matakai.

- Juriyar Gajiya Mai Ƙarfi: Yana jure wa zagayowar zafi na ≥15,000 (-50℃ zuwa 250℃) ba tare da lalata fuska ko lalacewar aiki ba - tsawon rai na sabis na 3× fiye da ƙananan layuka, wanda ke rage farashin gyara kayan aiki na dogon lokaci (misali, tsarin HVAC).

- Juriyar Girgiza & Juriyar Tsatsa: Ƙarfin juyewa ≥460 MPa yana tabbatar da kwanciyar hankali a tsarin yayin girgiza (ya dace da gwajin girgiza na IEC 60068-2-6); zaɓin zinc-plating yana ba da juriya ga feshin gishiri na awanni 96 (ASTM B117) don yanayin danshi ko lalata (misali, kayan aikin ruwa).

- Daidaitaccen Girma: Akwai shi a cikin kauri gama gari (0.15mm–0.8mm) da faɗi (10mm–200mm) tare da haƙuri ≤±0.005mm (kauri) da ≤±0.1mm (faɗi) - yana ba da damar yin tambari ta atomatik da haɗa shi cikin kayan masana'antu na yau da kullun.

Bayanan Fasaha

| Siffa | Darajar (Na yau da kullun) |

|---|---|

| Nisa Mai Kauri | 0.15mm – 0.8mm (na musamman har zuwa 1.2mm) |

| Nisa Mai Faɗi | 10mm - 200mm (faɗin da aka saba: 15mm, 20mm, 27mm) |

| Tsawon kowace Naɗi | 50m - 300m (tsawon da za a iya yankewa: ≥100mm) |

| Rabon Faɗaɗa Ma'aunin Zafi (Babban/Ƙaramin Layer) | ~4:1 |

| Yanayin Zafin Aiki | -50℃ zuwa 250℃ (ci gaba); Na ɗan gajeren lokaci: har zuwa 300℃ (≤awa 1) |

| Canjin Zafin Aiki | ±2℃ (a wurin kunnawa da aka ƙima, 80℃–200℃) |

| Ƙarfin Ragewa Tsakanin Fuska | ≥140 MPa |

| Ƙarfin Taurin Kai (Transverse) | ≥460 MPa |

| Ƙarawa (25℃) | ≥14% |

| Juriya (25℃) | 0.20 – 0.35 Ω·mm²/m |

| Taurin saman (Ra) | ≤0.8μm (ƙarshen niƙa); ≤0.4μm (ƙarshen da aka goge, zaɓi ne) |

Bayanin Samfura

| Abu | Ƙayyadewa |

|---|---|

| Ƙarshen Fuskar | gama niƙa (ba shi da oxide) ko kuma wanda aka yi da zinc/nickel (don ƙarfafa juriyar tsatsa) |

| Faɗi | ≤0.1mm/m (mahimmanci don daidaiton nakasassu na zafi iri ɗaya da kuma tambarin tambari) |

| Ingancin aiki | Dace da tambarin CNC, yanke laser, da lanƙwasawa; babu tsagewa a tsakanin fuskoki yayin sarrafawa (mafi ƙarancin radius mai lanƙwasa ≥3 × kauri) |

| Ingancin Haɗi | Haɗin fuska 100% (babu ramuka sama da 0.1mm², an tabbatar da su ta hanyar duba X-ray da gwajin ultrasonic) |

| Marufi | An rufe shi da injin tsotsa a cikin jakunkunan foil na aluminum masu jure da danshi tare da busar da itace; sandunan katako (don birgima) ko kwalaye masu hana lanƙwasawa (don zanen gado) don hana lalacewa |

| Keɓancewa | Daidaita zafin aiki (60℃–220℃), rufin saman, siffofi da aka riga aka buga (ga kowane fayilolin CAD na abokin ciniki), da kauri/faɗi mara daidaito |

Aikace-aikace na yau da kullun

- Kula da Zafin Masana'antu: Na'urorin auna zafin jiki na tanda na masana'antu, tukunyar ruwa, da tsarin HVAC; na'urorin auna zafin jiki na injunan ƙera filastik (suna aiki a zafin 120℃–200℃).

- Kariyar Zafi Mai Yawa: Na'urorin katse wutar lantarki na injinan lantarki (misali, famfunan masana'antu, na'urorin damfara) da na'urorin canza wutar lantarki—suna hana ƙonewa ta hanyar katse wutar lantarki a zafin 150℃–250℃.

- Motoci da Na'urorin Ruwa: Na'urori masu auna zafin jiki da kariya ga sassan injin (mota) da kayan aikin ruwa (masu jure girgiza da tsatsa na ruwan gishiri).

- Kayan Aiki Masu Daidaito: Abubuwan da ke daidaita zafin jiki don ma'aunin matsi, mitar kwarara, da na'urori masu auna MEMS - suna daidaita kurakuran faɗaɗa zafi don kiyaye daidaiton ma'auni.

- Kayan Aiki na Gida da Kasuwanci: Kariyar zafi mai yawa ga na'urorin dumama ruwa na lantarki, na'urorin sanyaya daki, da kuma na'urorin sanyaya daki na kasuwanci (ingantaccen aiki a yanayin zafi mai yawa).

Tankii Alloy Material yana aiwatar da ingantaccen kula da inganci ga tsiri biyu na bimetallic na TTБ2013/TM-2/108SP: kowane rukuni yana fuskantar gwajin yanke fuska, gwajin kwanciyar hankali na zafi mai zagaye 1000, duba girma (micrometry na laser), da daidaita zafin jiki. Ana samun samfuran kyauta (100mm × 20mm) da cikakkun rahotannin aiki (gami da lanƙwasa na zafi da lanƙwasa) idan an buƙata. Ƙungiyarmu ta fasaha tana ba da tallafi na musamman - kamar inganta lanƙwasa na ƙarfe don takamaiman yanayin zafi na aiki da jagorar dacewa tare da hanyoyin haɗa masana'antu - don tabbatar da cewa lanƙwasa ya cika ainihin buƙatun aikace-aikacen masana'antu na Eurasia da na duniya.

Rubuta saƙonka a nan ka aika mana da shi

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama