Wayar Copper Mai Zafi Mai Zafi Mai Launi ...

Wayar Copper Mai Zafi Mai Zafi Mai Launi ...

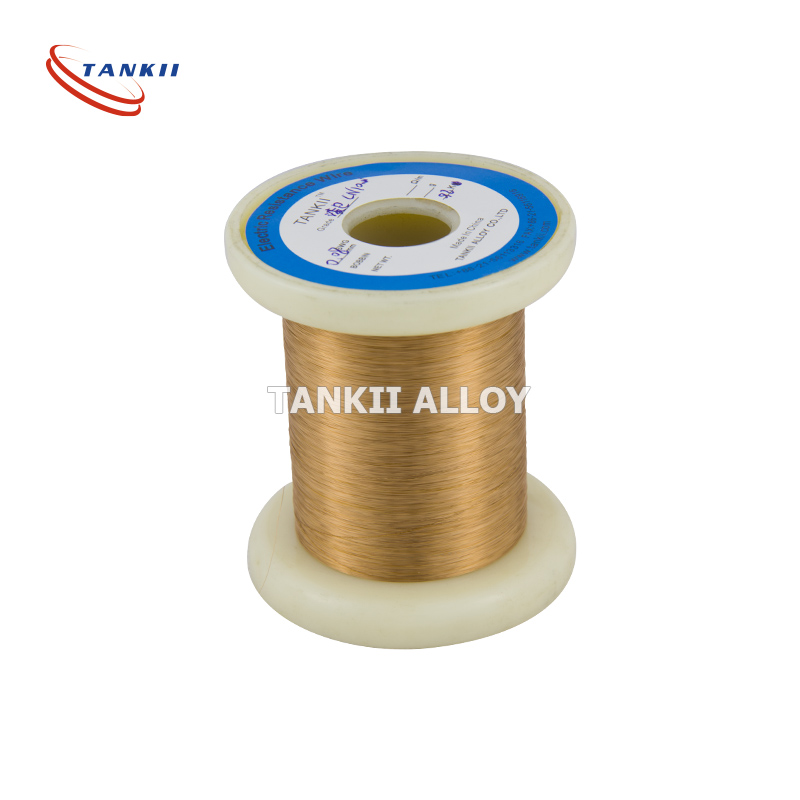

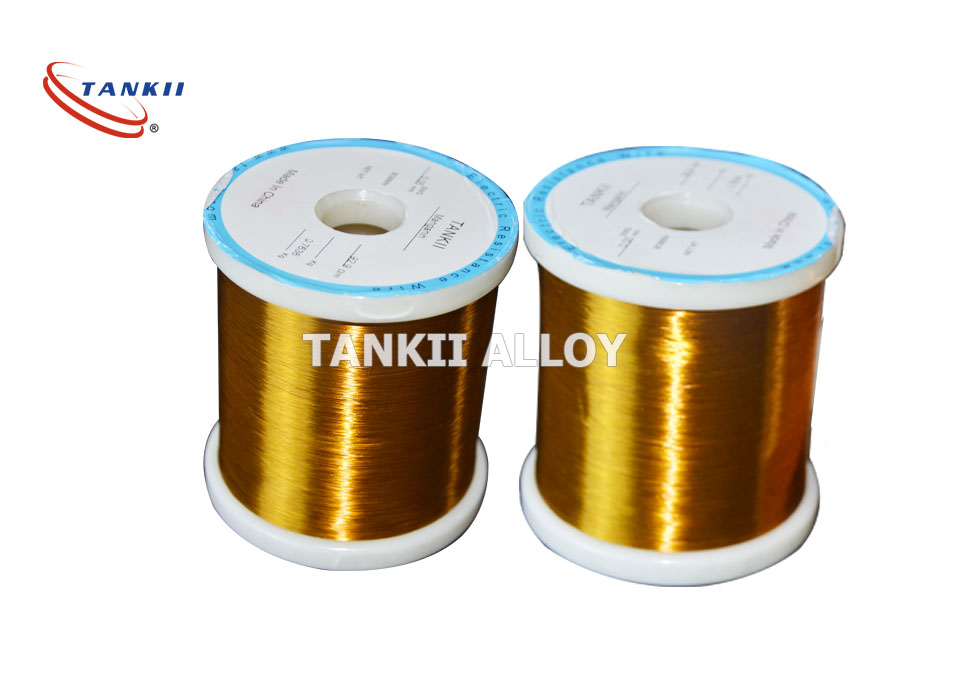

Wayar maganadisu ko waya mai enamel waya ce ta jan ƙarfe ko aluminum wadda aka lulluɓe da siririn rufin rufi. Ana amfani da ita wajen gina na'urori masu canza wutar lantarki, inductors, injuna, janareto, lasifika, masu kunna kan faifai, na'urorin lantarki, na'urorin girkawa na guitar da sauran aikace-aikacen da ke buƙatar matsewar waya mai rufi.

Wayar kanta galibi ana yin tagulla mai cike da annealed, wanda aka tace ta hanyar lantarki. Wani lokaci ana amfani da wayar maganadisu ta aluminum don manyan na'urori masu canza wutar lantarki da injina. Yawanci ana yin rufin ne da kayan fim ɗin polymer masu ƙarfi maimakon enamel, kamar yadda sunan zai iya nunawa.

Mai jagoranci

Mafi kyawun kayan aiki don amfani da waya mai maganadisu sune ƙarfe tsarkakakken ƙarfe marasa ƙarfe, musamman jan ƙarfe. Lokacin da aka yi la'akari da buƙatun sinadarai, na zahiri, da na injiniya, jan ƙarfe ana ɗaukarsa a matsayin jagora na farko da za a zaɓa don wayar maganadisu.

Sau da yawa, wayar maganadisu tana ƙunshe da jan ƙarfe mai cikakken annealed, wanda aka tsarkake ta hanyar lantarki don ba da damar yin lanƙwasa kusa yayin yin na'urorin lantarki. Ana amfani da ma'aunin jan ƙarfe mara iskar oxygen mai ƙarfi don aikace-aikacen zafin jiki mai yawa wajen rage yanayi ko a cikin injina ko janareto da iskar hydrogen ta sanyaya.

Ana amfani da wayar maganadisu ta aluminum a matsayin madadin manyan na'urori masu canza wutar lantarki da injina. Saboda ƙarancin wutar lantarki, wayar aluminum tana buƙatar yanki mai girman sashe sau 1.6 fiye da wayar jan ƙarfe don cimma juriyar DC iri ɗaya.

Rufewa

Ko da yake an bayyana wayar da aka yi da "enameled", a zahiri ba a shafa mata fenti ko vitreous enamel da aka yi da foda gilashi mai haɗe ba. Wayar maganadisu ta zamani yawanci tana amfani da yadudduka ɗaya zuwa huɗu (idan akwai waya mai nau'in quad-film) na murfin fim ɗin polymer, galibi na abubuwa biyu daban-daban, don samar da Layer mai tauri da ci gaba da rufewa. Fina-finan toshe waya na maganadisu suna amfani da (domin ƙara yawan zafin jiki) polyvinyl formal (Formvar), polyurethane, polyamide, polyester, polyester-polyimide, polyamide-polyimide (ko amide-imide), da polyimide. Wayar maganadisu mai rufi da Polyimide tana iya aiki har zuwa 250 °C. Sau da yawa ana ƙara rufin waya mai kauri murabba'i ko murabba'i ta hanyar naɗe shi da tef ɗin polyimide ko fiberglass mai zafi, kuma an cika windings ɗin da fenti mai rufi da varnish mai rufi don inganta ƙarfin rufewa da amincin naɗaɗɗen na dogon lokaci.

Ana ɗaure na'urorin da ke ɗaukar kansu da waya da aka lulluɓe da aƙalla layuka biyu, mafi bayansu shine thermoplastic wanda ke haɗa juyawar tare lokacin da aka dumama.

Ana kuma amfani da wasu nau'ikan rufin kamar zaren fiberglass mai varnish, takardar aramid, takardar kraft, mica, da fim ɗin polyester sosai a duk faɗin duniya don aikace-aikace daban-daban kamar transformers da reactors. A ɓangaren sauti, ana iya samun waya ta ƙarfe, da sauran abubuwan hana ruwa, kamar auduga (wani lokacin ana cika ta da wani nau'in abin hana ruwa/mai kauri, kamar kakin zuma) da polytetrafluoroethylene (Teflon). Tsoffin kayan hana ruwa sun haɗa da auduga, takarda, ko siliki, amma waɗannan suna da amfani ne kawai don aikace-aikacen ƙarancin zafin jiki (har zuwa 105°C).

Domin sauƙin ƙera wasu igiyoyin maganadisu masu ƙarancin zafin jiki, suna da rufin da za a iya cirewa ta hanyar zafin haɗakarwa. Wannan yana nufin cewa ana iya yin haɗin lantarki a ƙarshen ba tare da cire rufin ba tukuna.

| Nau'in Enamel | Polyester | Polyester da aka Gyara | polyester-imide | Polyamide-imide | polyester-imide / Polyamide-imide |

| Nau'in Rufi | PEW/130 | PEW(G)/155 | EIW/180 | EI/AIW/200 | EIW(EI/AIW)220 |

| Ajin zafi | 130, AJI B | 155, AJI NA F | 180, AJI H | 200, AJI C | 220, AJI N |

| Daidaitacce | IEC60317-0-2IEC60317-29 MW36-A | IEC60317-0-2IEC60317-29MW36-A | IEC60317-0-2IEC60317-29 MW36-A | IEC60317-0-2IEC60317-29 MW36-A | IEC60317-0-2IEC60317-29 MW36-A |

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama