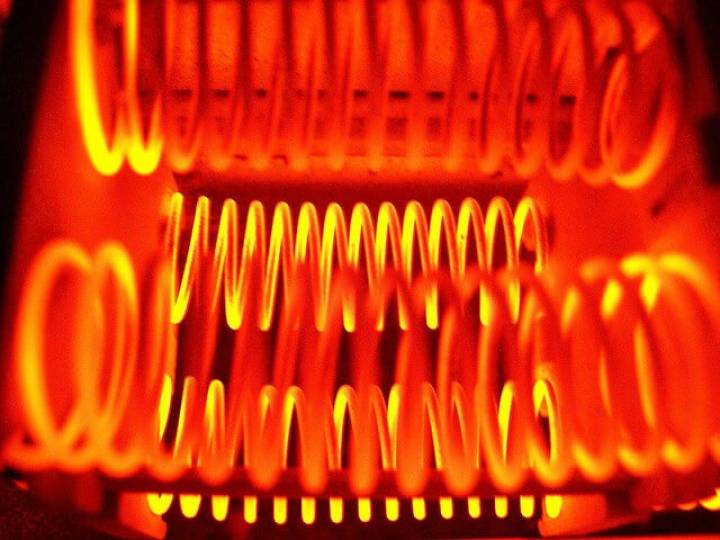

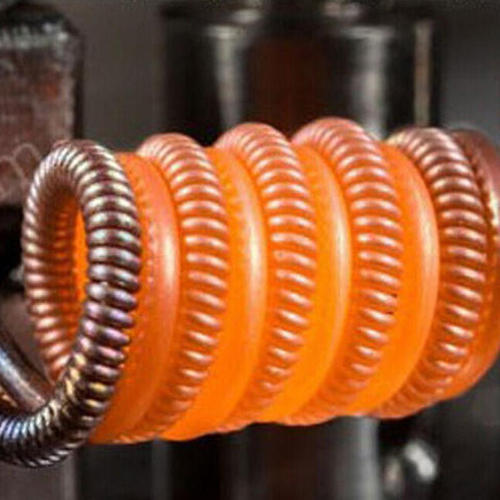

FeCrAl 0Cr25Al5 na'urar dumama murhu ta lantarki mai murhu mai dumama

Babban Halaye na waya mai juriya ga dumama

| Nau'in Gami | diamita (mm) | Juriya (μΩm)(20°C) | Taurin kai Ƙarfi (N/mm²) | Tsawaita (%) | Lanƙwasawa Lokuta | Mafi girma Sabis Zafin jiki (°C) | Rayuwar Aiki (awanni) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| SUNA | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| BABBAN ASIRI | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| ABUBUWAN DA KE CIKI | Re | dama | dama | dama | dama | dama | dama | dama |

| Fe | Hutu | Hutu | Hutu | Hutu | Hutu | Hutu | Hutu | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| MAFI GIRMAN ZAFI (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| JURIYA 20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| YAWAN JIN DAƊI (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| MUSAYAR ZAFI | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| ƘIDAR (KJ/m·h·oC) | ||||||||

| ƙimar faɗaɗawa (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| wurin narkewa (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Ƙarfin taurin kai (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| tsawaitawa (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| bambancin yanki (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Mitar lanƙwasawa (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| taurin kai (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Tsarin micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| kadarar maganadisu | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

| Diamita (mm) | Juriya (mm) | Diamita (mm) | Juriya (mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

| Kauri (mm) | Juriya (mm) | Faɗi (mm) | Juriya (mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

Mu masana'antun waya ne masu juriya ga dumama sun haɗa da

Wayar FeCrAL, Wayar NiCr, Wayar CuNi:

II Babban Riba da Aikace-aikacen

A. Sigar jiki:

1) Diamita na waya: 0.025 ~ 15mm

2) Tsarkakken nickel yana da ikon jure yanayin zafi mai tsanani ba tare da lalacewa ba.

zafin jiki yana da kimanin 600°C

3) Ana samun wayar nickel a cikin zare ɗaya ko kuma a cikin tsarin zare da yawa. Ana samunta daga hannun jari ko dai a ɓoye, ko kuma a rufe ta da ruwa.

B. Halaye:

1) Daidaito mai kyau

2) Tsarin saman iri ɗaya da kyau ba tare da tabo ba

3) Kyakkyawan ikon ƙirƙirar na'ura

C. Babban aikace-aikace da manufa ta gabaɗaya:

1) Ana iya amfani da wannan wayar sosai a cikin takamaiman madaidaitan madaukai na transistor, anodes na bututun lantarki,

jakunkunan kayan lantarki / wayoyi masu guba don fitilu da kuma ragar waya. Haka kuma ana amfani da su a cikin nau'in tsiri don nau'ikan

aikace-aikace, gami da batirin Ni-Cd

2) Ana amfani da shi don kebul, Lead-in-Wire don fitilu, tallafin bututun lantarki, zane mai haɗa lantarki na waya

inda yanayin zafi ya wuce waɗanda jan ƙarfe ya dace da su, saka waya

3) Aikace-aikacen da aka saba amfani da su sun haɗa da: ƙarewa don abubuwan dumama kamar a cikin tanda, na'urorin fitar da robobi, da tanderu.

Tallafin filament da wayoyi masu guba a masana'antar hasken wuta

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama