Barka da zuwa gidajen yanar gizon mu!

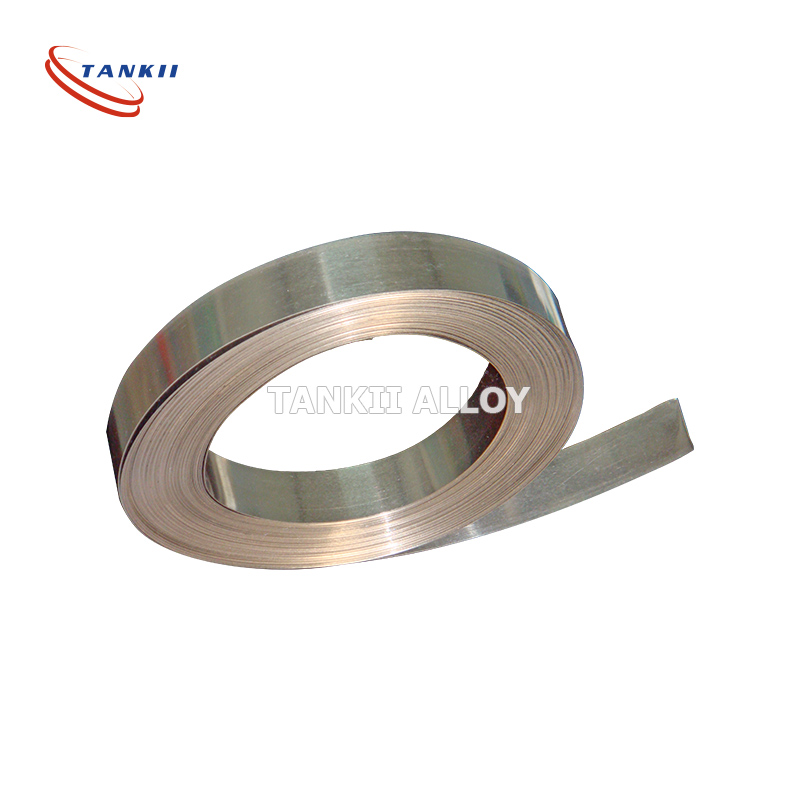

Tsarin juriya na ƙarfe na Fecral 0Cr15Al5 ta masana'anta

Fecral0Cr15Al5Tsarin juriya na ƙarfe ta masana'anta

| Matsayi | |

| Girman | kauri:0.05-3mm faɗi:4-250mm |

| saman | yankewa mai haske |

| Nauyi | 5-200kg/mirgina, gwargwadon adadin abokan ciniki |

| Juriya | 1.3±0.05μΩ.m |

| Taurin kai (HV) | 180-210HV |

| Ƙarawa | ≥16% |

| Matsayi | Mafi girman zafin jiki | Juriya | Tauri | Ƙarfin tauri | Ƙarawa |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr25Ni20 | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Matsayi | Sinadaran da ke cikin sinadarai% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | daidaito |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | daidaito |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | daidaito |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | daidaito | <0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | daidaito |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | daidaito |

| Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | daidaito |

Kamfanin Shanghai Tankii Alloy Material Co., Ltd. ya mayar da hankali kan samar da ƙarfe na nichrome, wayar thermocouple, ƙarfe na fecral, ƙarfe na daidai, ƙarfe na nickel na jan ƙarfe, ƙarfe na feshi na zafi da sauransu a cikin nau'in waya, takarda, tef, tsiri, sanda da farantin.

Mun riga mun sami takardar shaidar ingancin tsarin ISO 9001 da kuma amincewa da tsarin kariyar muhalli na ISO 14001. Muna da cikakken tsarin ingantaccen tsarin tacewa, rage sanyi, zane da kuma maganin zafi da sauransu. Muna alfahari da samun damar yin bincike da tsara ayyuka masu zaman kansu.

Rubuta saƙonka a nan ka aika mana da shi

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama