CuSn4 CuSn6 CuSn8 Phosphor Tin Tagulla Mai Lanƙwasa C5191

Cikakken Bayani game da CuSn4 CuSn6 CuSn8 Phosphor Tin Tagulla Coil Strip C5191:

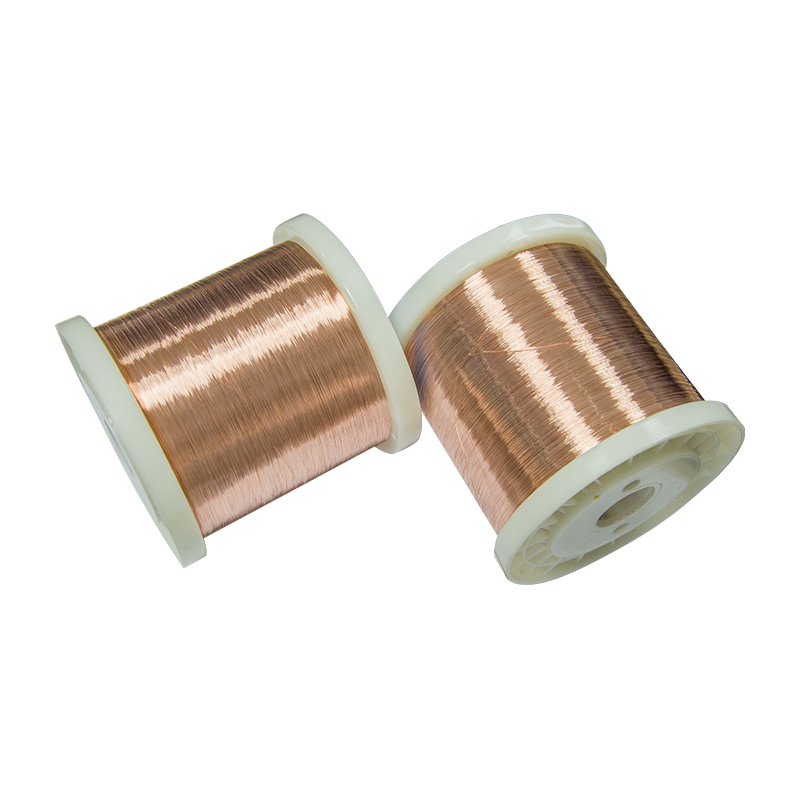

CuSn4 CuSn6 CuSn8 Phosphor Tin Tagulla Nada Zirin

CuSn6 - UNS.C51900 Phosphor Bronze Alloys, wanda shine tagulla mai kauri 6% wanda aka bambanta ta hanyar haɗin ƙarfi da ƙarfin lantarki. Ana amfani da shi don maɓuɓɓugan haɗi da masu ɗaukar wutar lantarki a cikin hulɗa. Daga cikin tagulla mai kauri 4-8% C51900 yana nuna babban ƙarfin lantarki, mafi girman ƙarfin da za a iya isa gare shi ya fi C51100 da C51000 girma sosai. Ta hanyar ƙarin ƙarin tenpering bayan tsarin samar da sanyi, ana iya ƙara inganta lanƙwasawa.

Sinadarin sinadarai na Phosphor C51900

| Labarai | Sinadarin sinadarai | |||||

| GB | UNS | EN | JIS | Ku% | Sn% | P% |

| QSn6.5-0.1 | C51900 | CuSn6 | C5191 | Rem | 5.5-7.0 | 0.03-0.35 |

| Sinadarin Sinadarai | |||

| % | |||

| Sn | P | Cu | kazanta |

| 7.0~9.0 | 0.15~0.35 | Bal. | ≤0.1 |

Kayayyakin injina na Phosphor Bronze

| Kayayyakin Inji | |||||

| Mai halin ɗaci | TS(N/mm²) | Tsawaita (%) | Taurin kai (Hv) | ||

| M | O | O60 | ≥345 | ≥40 | / |

| Y4 | 1/4H | H01 | 390-510 | ≥35 | 100-160 |

| Y2 | 1/2H | H02 | 490-610 | ≥8 | 150-200 |

| Y | H | H04 | 590-705 | ≥5 | 190-230 |

| T | EH | H06 | 585-740 | / | 200-240 |

| TY | SH | H08 | ≥735 | / | ≥230 |

| Kayayyakin injina | |||||||

| Jiha | Taurin kai (HV) | Gwajin tashin hankali | Gwajin lanƙwasawa | ||||

| kauri mm | ƙarfin tensile MPa | tsawaita % | kauri | kusurwoyi | ID | ||

| 0 | - | 0.1-5.0 | ≥315 | ≥42 | ≤1.6 | 180° | Kauri kashi 50% |

| 1/4H | 100-160 | 0.1-5.0 | 390-510 | ≥35 | ≤1.6 | 180° | Kauri 100% |

| 1/2H | 150-205 | 0.1-5.0 | 490-610 | ≥20 | ≤1.6 | 180° | Kauri 150% |

| H | 180-230 | 0.1-5.0 | 590-685 | ≥8 | ≤1.6 | 180° | Kauri 200% |

| EH | 200-240 | 0.1-0.2 | 635-720 | - | - | - | - |

| >0.2-5 | ≥5 | - | - | - | |||

| SH | ≥210 | 0.1-5.0 | ≥690 | - | - | - | - |

Siffofin Tagulla na Phosphor C51900 don Zane-zanen Tagulla na Phosphor

- Ƙara yawan aiki ≥25%

- Modulus na sassauci:125GPa

- Ƙarfin samarwa: ≥90% ƙarfin tensile

- Aikin gajiya

- Aikin plating

- Kyakkyawan aikin walda

- Kyakkyawan aiki mai sanyi, halayen zane mai zurfi, halayen lankwasawa

Phosphor Bronze C51900 Aikace-aikacen yau da kullun

Ana amfani da Phosphor Bronze sosai a cikin ramin CPU na na'urar kwamfuta, tashar mota, maɓallan wayar hannu, masu haɗin lantarki da sauran filayen lantarki masu fasaha.

Hotunan cikakken bayani game da samfurin:

Jagorar Samfuri Mai Alaƙa:

Muna ɗaukar "mai sauƙin amfani ga abokan ciniki, mai da hankali kan inganci, mai haɗaka, mai ƙirƙira" a matsayin manufofi. "Gaskiya da gaskiya" shine tsarin gudanarwarmu mafi kyau ga CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191, Samfurin zai wadatar ga duk faɗin duniya, kamar: Colombia, Rwanda, Angola, Za mu iya biyan buƙatun abokan ciniki daban-daban a gida da waje. Muna maraba da sabbin abokan ciniki da tsoffin su zo su yi shawarwari da mu. Gamsuwar ku ita ce kwarin gwiwarmu! Bari mu yi aiki tare don rubuta sabon babi mai ban mamaki!

Ma'aikatan kula da abokan ciniki da masu sayar da kayayyaki suna da haƙuri sosai kuma duk sun ƙware a Turanci, isowar kayan kuma yana da matuƙar dacewa, mai samar da kayayyaki mai kyau.

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama