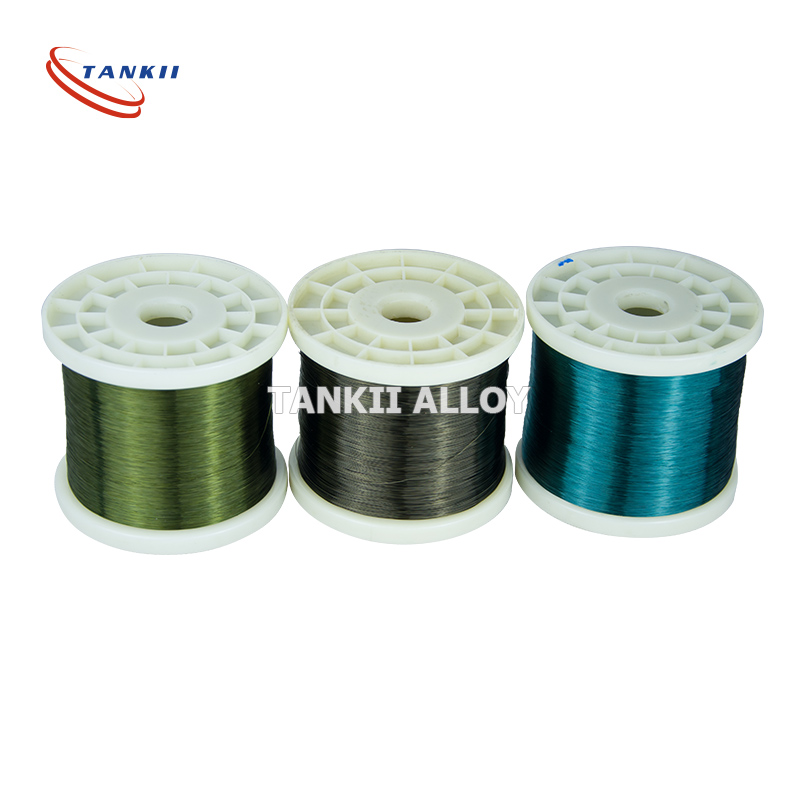

Wayar jan ƙarfe mai nauyin thermal aji C / 200*C ANSI TYPE MW35C ko IEC 317-13. Wayar juyawa mai rufi biyu mai rufi da enamel mai rufi da polyester-imide da polyamide-imide

Wayar jan ƙarfe Ajin zafi C/ 200*C ANSI TYPE MW35C ko IEC 317-13. Polyester-imide dapolyamide-imideWaya mai rufi biyu mai rufi da enamel

Bayanin Samfurin

An yi amfani da waɗannan wayoyi masu juriya da aka yi da enamel sosai don juriya na yau da kullun, motoci

sassa, masu jure wa juna, da sauransu ta amfani darufin rufisarrafa kayan aiki ya fi dacewa da waɗannan aikace-aikacen, yana amfani da cikakkiyar fa'idodin keɓancewa na rufin enamel.

Har ila yau, za mu yi amfani da shafi na enamelrufin rufina waya mai daraja kamar azurfa da platinum idan an yi oda. Da fatan za a yi amfani da wannan samarwa a kan oda.

Nau'in Wayar Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

Nau'in Rufi

| Sunan da aka yi wa rufi da enamel | Matakin Zafi°C (lokacin aiki awanni 2000) | Sunan Lambar | Lambar GB | ANSI. NAUYI |

| Wayar da aka yi da polyurethane | 130 | UEW | QA | MW75C |

| Wayar da aka yi da polyester enamel | 155 | PEW | QZ | MW5C |

| Wayar da aka yi da enamel mai polyester-imide | 180 | EIW | QZY | MW30C |

| Wayar polyester-imide da polyamide-imide mai rufi biyu mai rufi da enamel | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Wayar da aka yi da enamel mai polyamide-imide | 220 | AIW | QXY | MW81C |

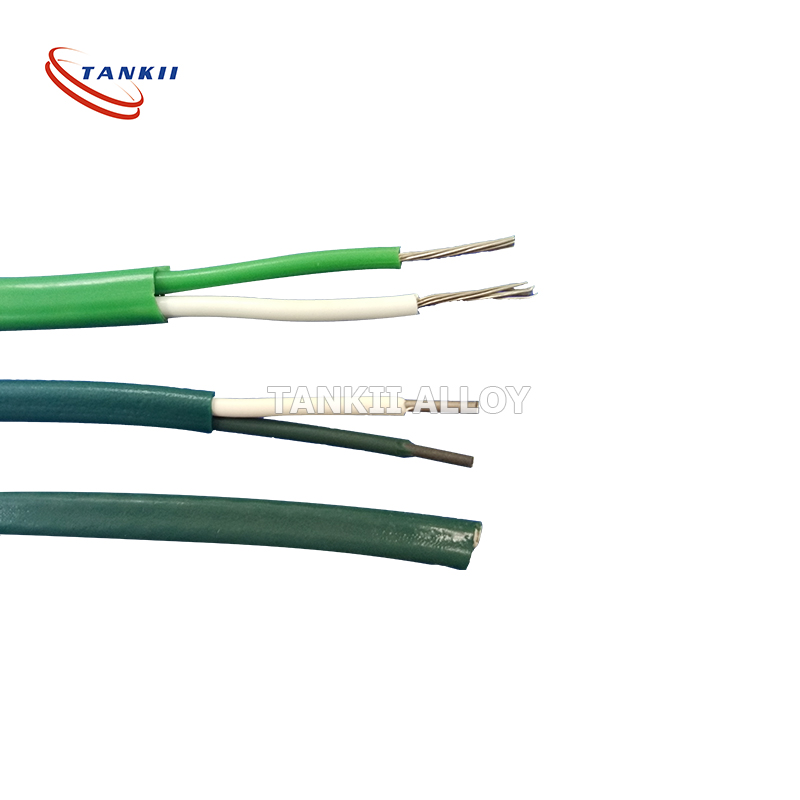

Nau'in Waya Mai Kama da Bare

Wayar da za mu iya yi da enamel ita ce waya mai ƙarfe-nickel, waya ta Constantan, waya ta Manganin. Wayar Kama, waya ta NiCr, waya ta FeCrAl da sauransu waya mai ƙarfe.

| babban kadarori nau'in | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| babban sinadarai abun da ke ciki | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | hutawa | hutawa | hutawa | hutawa | hutawa | hutawa | hutawa | hutawa | hutawa | hutawa | hutawa | ||

| matsakaicin aiki zafin jiki | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| yawa g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| juriya a 20°C | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.20± 5% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | ||

| zafin jiki ma'aunin yawan juriya | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| tensile ƙarfi mpa | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| tsawaitawa | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| narkewa maki °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| ma'aunin yawan kwararar wutar lantarki | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

Wayar dumama ta nicr8020

1. Game da waya ta Nichrome

Gilashin Nichrome ya haɗa da tsantsar nickel, NiCr gami, Fe-Cr-Al gami da jan ƙarfe nickel gami.

Haɗaɗɗen nickel chrome: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, tsantsar nickel Ni200 da Ni201

2. Babban Amfani da Aikace-aikacen

1. Nickel-chromium, gami da nickel-chromium tare da juriya mai ƙarfi da karko, juriyar tsatsa, juriyar iskar shaka a saman yana da kyau, mafi kyau a ƙarƙashin zafin jiki mai yawa da ƙarfin girgizar ƙasa, kyakkyawan juriya, kyakkyawan aiki da kuma sauƙin walda.

2. Kayayyakinmu sun shafi masana'antar sinadarai, tsarin ƙarfe, masana'antar gilashi, masana'antar yumbu, yankin kayan aikin gida da sauransu.

3. Haɗin sinadarai:

| Alamar kasuwanci | Sinadarin sinadarai | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Ba fiye da | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | saura | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | saura |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | saura |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | saura |

Idan samfurin yana kan matsayin "M", ya kamata a bi ƙa'idar GB/T1234-1995

Juriya:

| Alamar kasuwanci | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| diamita mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| juriya (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama