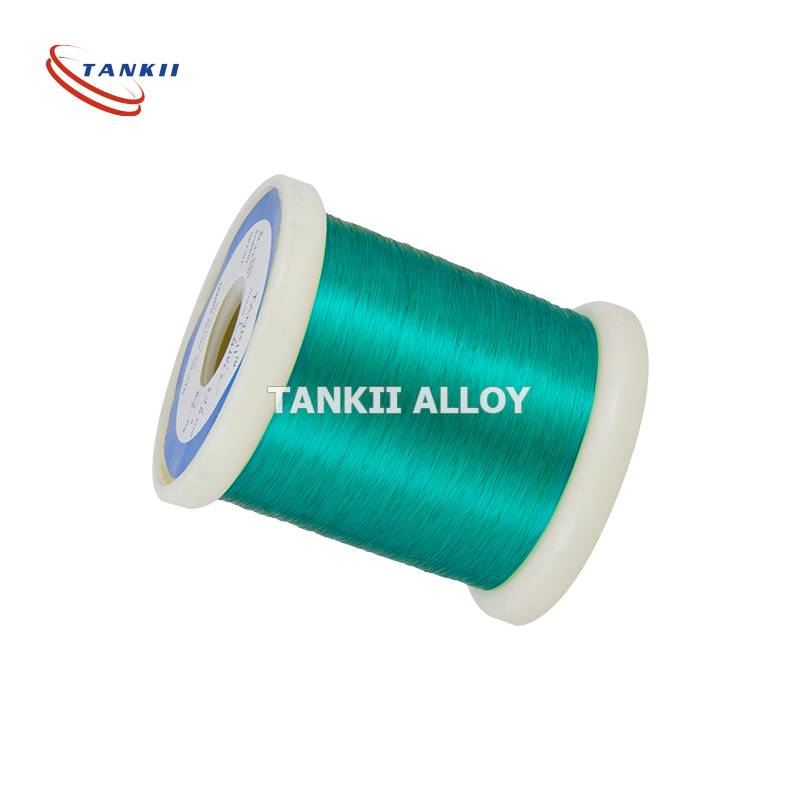

Wayar jan ƙarfe mai zagaye da aka yi da nailan ta aji F/wayar polyester mai gyaggyara

Aji na Fnailan/an gyara polyester mai zane mai zane mai zaneWayar jan ƙarfe

Bayanin Samfurin

An yi amfani da waɗannan wayoyi masu juriya da aka yi da enamel sosai don juriya na yau da kullun, motoci

sassa, masu jure wa juna, da sauransu ta amfani darufin rufisarrafa kayan aiki ya fi dacewa da waɗannan aikace-aikacen, yana amfani da cikakkiyar fa'idodin keɓancewa na rufin enamel.

Har ila yau, za mu yi amfani da shafi na enamelrufin rufina waya mai daraja kamar azurfa da platinum idan an yi oda. Da fatan za a yi amfani da wannan samarwa a kan oda.

Nau'in waya mai ɗauke da alloy

Wayar da za mu iya yi da enamel ita ce waya mai ƙarfe-nickel, waya ta Constantan, waya ta Manganin. Wayar Kama, waya ta NiCr, waya ta FeCrAl da sauransu waya mai ƙarfe.

Nau'in rufin

| Sunan da aka yi wa rufi da enamel | Matakin Zafi°C (lokacin aiki awanni 2000) | Sunan Lambar | Lambar GB | ANSI. NAUYI |

| Wayar da aka yi da polyurethane | 130 | UEW | QA | MW75C |

| Wayar da aka yi da polyester enamel | 155 | PEW | QZ | MW5C |

| Wayar da aka yi da enamel mai polyester-imide | 180 | EIW | QZY | MW30C |

| Wayar polyester-imide da polyamide-imide mai rufi biyu mai rufi da enamel | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Wayar da aka yi da enamel mai polyamide-imide | 220 | AIW | QXY | MW81C |

Abubuwan Sinadarai, %

| Cu | Bi | Sb | As | Fe | Ni | Pb | S | Zn | Umarnin ROHS | |||

| Cd | Pb | Hg | Cr | |||||||||

| 99.90 | 0.001 | 0.002 | 0.002 | 0.005 | - | 0.005 | 0.005 | - | ND | ND | ND | ND |

Sifofin Jiki

| Wurin Narkewa - Liquidus | 1083ºC |

| Wurin Narkewa - Solidus | 1065ºC |

| Yawan yawa | 8.91 gm/cm3@ 20 ºC |

| Takamaiman Nauyi | 8.91 |

| Juriyar Lantarki | 1.71 microhm-cm @ 20 ºC |

| Lantarki Mai Watsa Wutar Lantarki** | 0.591 MegaSiemens/cm @ 20 ºC |

| Tsarin kwararar zafi | 391.1 W/m ·oK a 20 C |

| Ma'aunin Faɗaɗawar Zafi | 16.9 ·10-6 a kowace Celsius (20-100 ºC) |

| Ma'aunin Faɗaɗawar Zafi | 17.3 ·10-6 a kowace Celsius (20-200 ºC) |

| Ma'aunin Faɗaɗawar Zafi | 17.6·10-6 a kowace Celsius(20-300 ºC) |

| Ƙarfin Zafi na Musamman | 393.5 J/kg ·oK a 293 K |

| Modulus na sassauci a cikin tashin hankali | 117000 Mpa |

| Modulus na Tauri | 44130 Mpa |

Amfani da takardar jan ƙarfe

1) Maɓuɓɓugan wutar lantarki da wutar lantarki, maɓallan wuta

2) Firam ɗin jagora

3) Masu haɗawa da sandunan juyawa

3) Filin PCB

4) Kebul na sadarwa, Kebul na sulke, Babban allon wayar hannu

5) Lamination na samar da batirin ion tare da fim ɗin PI

6) Kayan PCB mai tarawa (mai tallafawa lantarki)

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama