C5191 C5210 Phosphor Bronze Copper Waya don Kayan Aikin Lantarki

Sinadarin Sinadarai

| Sinadarin | Bangaren |

| Sn | 5.5-7.0% |

| Fe | ≤0.1% |

| Zn | ≤0.2% |

| P | 0.03-0.35% |

| Pb | ≤0.02% |

| Cu | Daidaito |

InjiniyanciKadarorin

| Alloy | Mai halin ɗaci | Ƙarfin Taurin KaiN/mm2 | Ƙarawa % | Taurin HV | Bayani |

| CuSn6 | O | ≥290 | ≥40 | 75-105 | |

| 1/4H | 390-510 | ≥35 | 100-160 | ||

| 1/2H | 440-570 | ≥8 | 150-205 | ||

| H | 540-690 | ≥5 | 180-230 | ||

| EH | ≥640 | ≥2 | ≥200 |

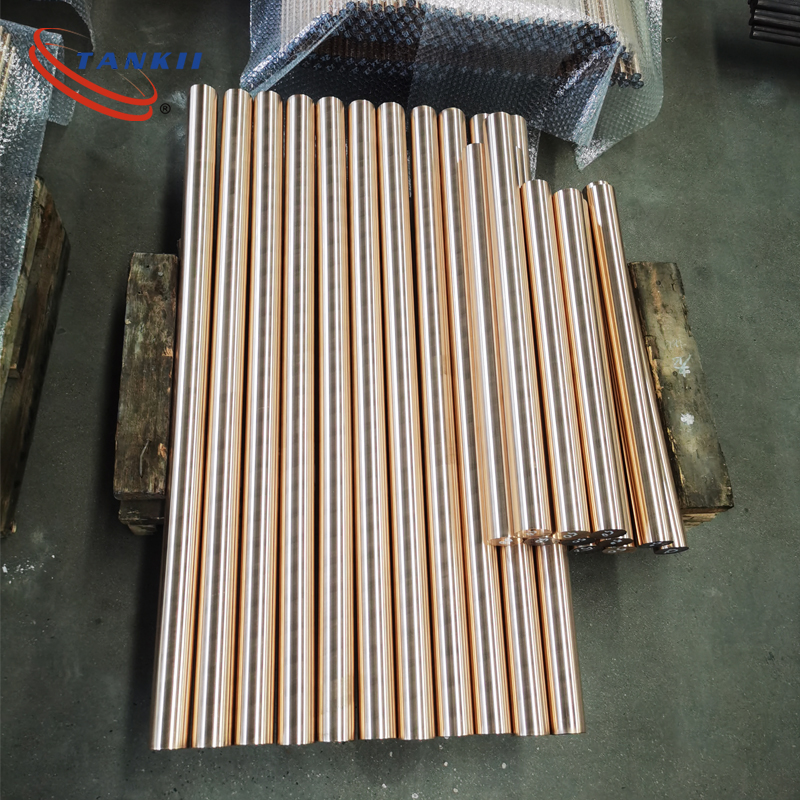

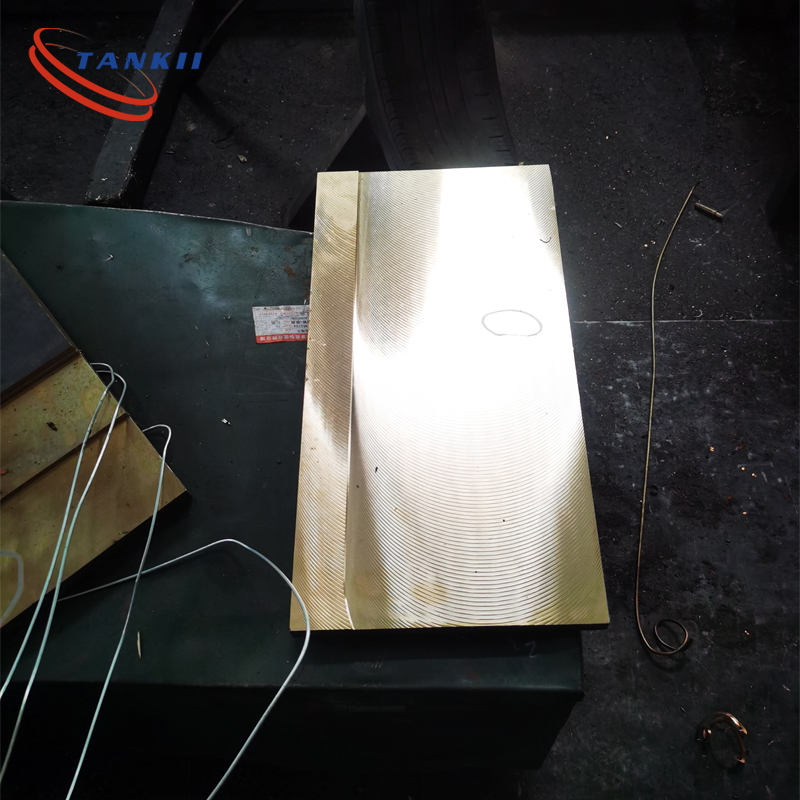

1. Kauri: 0.01mm–2.5mm,

2. Faɗi: 0.5–400mm,

3. Haushi: O, 1/4H, 1/2H, H, EH, SH

4. Mai sauƙin muhalli, yana ba da buƙatu daban-daban kan abubuwa masu haɗari, kamar gubar, ƙasa da 100ppm; Rahoton Rohs ya bayar.

5. Bayar da takardar shaidar injin niƙa ga kowane nadi, tare da kuri'a, ƙayyadaddun bayanai, ƙimar NW, GW, HV, rahoton MSDS, SGS.

7. Tsananin juriya kan kauri da faɗi, da kuma sauran abubuwan da suka shafi inganci.

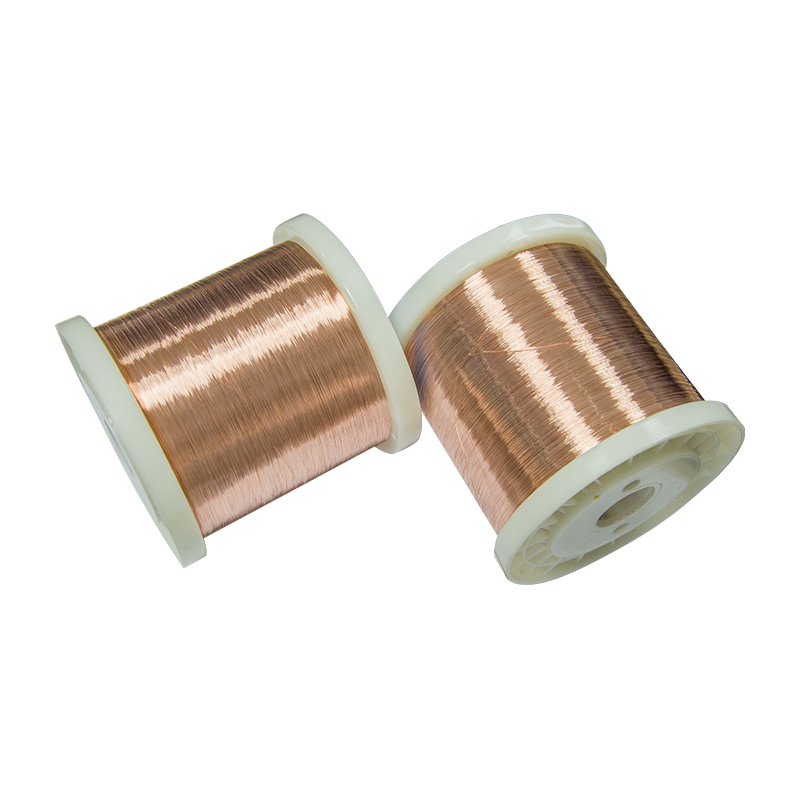

8. Ana iya keɓance nauyin na'urar.

9. Marufi: Marufi mai tsaka-tsaki, jakar filastik, layin takarda a cikin pallet ɗin katako ko akwati. Nauyi 1 ko da yawa a cikin pallet 1 (ya dogara da faɗin na'urar), alamar jigilar kaya. GP ɗaya mai inci 20 zai iya ɗaukar tan 18-22.

10. Lokacin jagora: kwanaki 10-15 bayan PO.

Nau'ikan samfura

-

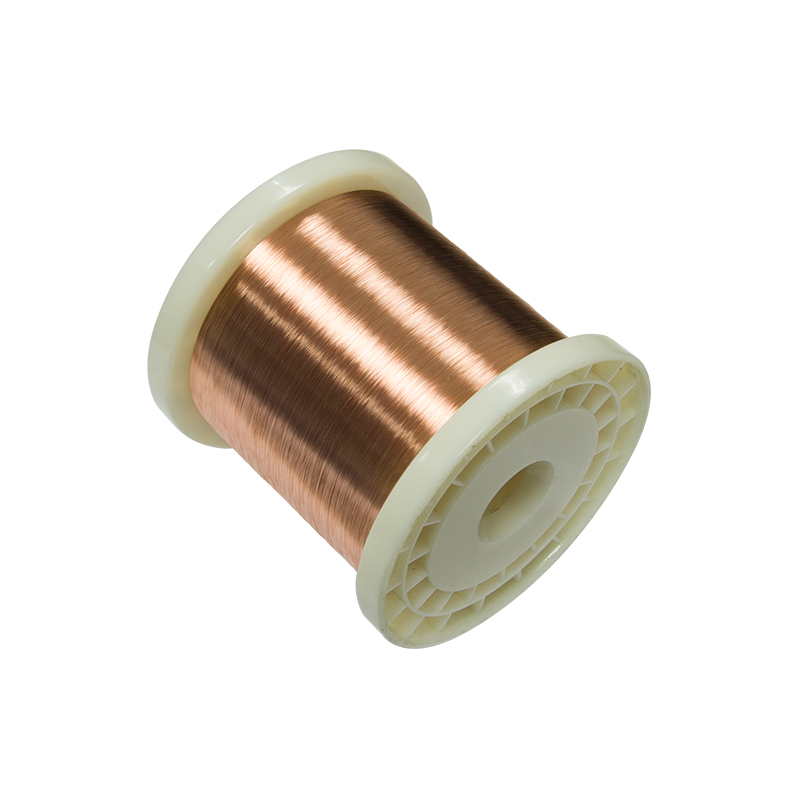

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama