ASME Sfa 5.14 Ernicr-3 Nickel Alloy 80 Inconel 600 Alloy MIG Wayar Walda TIG Rod Welding

Inconel 600 wani ƙarfe ne na nickel-chromium wanda ke da kyakkyawan juriya ga acid na halitta kuma ana amfani da shi sosai a cikin sarrafa fatty acid. Babban sinadarin nickel na Inconel 600 yana ba da kyakkyawan juriya ga tsatsa a ƙarƙashin yanayi mai ragewa, da kuma yawan sinadarin chromium ɗinsa, juriya a ƙarƙashin yanayin oxidizing. An yi amfani da ƙarfen sosai wajen samarwa da sarrafa sinadarai masu guba da sinadarin caustic soda da alkali. Alloy 600 kuma kyakkyawan abu ne don aikace-aikacen zafin jiki mai yawa wanda ke buƙatar haɗuwa da juriyar zafi da tsatsa. Kyakkyawan aikin ƙarfe a cikin yanayin halogen mai zafi ya sa ya zama zaɓi mai shahara don hanyoyin chlorination na halitta. Alloy 600 kuma yana tsayayya da oxidation, carburization, da nitridation.

A cikin samar da titanium dioxide ta hanyar amfani da chloride, titanium oxide na halitta (illmenite ko rutile) da iskar chlorine mai zafi suna amsawa don samar da titanium tetrachloride. An yi amfani da Alloy 600 cikin nasara a cikin wannan tsari saboda kyakkyawan juriyarsa ga lalatawa ta hanyar iskar chlorine mai zafi. Wannan gami ya sami amfani mai yawa a cikin tanderu da filin maganin zafi saboda kyakkyawan juriyarsa ga iskar shaka da sikelinsa a 980°C. Haka kuma, ƙarfen ya sami amfani mai yawa wajen sarrafa yanayin ruwa, inda ƙarfen bakin ƙarfe suka gaza ta hanyar fashewa. An yi amfani da shi a cikin wasu na'urorin nukiliya, ciki har da injin tururi da tsarin bututun ruwa na farko.

Sauran aikace-aikacen da aka saba amfani da su sune tasoshin sarrafa sinadarai da bututun mai, kayan aikin kula da zafi, kayan aikin injin jirgin sama da na'urorin iska, sassan lantarki, da kuma na'urorin sarrafa nukiliya.

Sinadarin Sinadarai

| Matsayi | Ni% | Mn% | Fe% | Si% | Cr% | C% | Ku% | S% |

| Inconel 600 | Mafi ƙarancin 72.0 | Matsakaicin 1.0 | 6.0-10.0 | Matsakaicin 0.50 | 14-17 | Matsakaicin 0.15 | Matsakaicin 0.50 | Matsakaicin 0.015 |

Bayani dalla-dalla

| Matsayi | Tsarin Burtaniya | Werkstoff Nr. | UNS |

| Inconel 600 | BS 3075 (NA14) | 2.4816 | N06600 |

Sifofin Jiki

| Matsayi | Yawan yawa | Wurin narkewa |

| Inconel 600 | 8.47 g/cm3 | 1370°C-1413°C |

Kayayyakin Inji

| Inconel 600 | Ƙarfin Taurin Kai | Ƙarfin Ba da Kyauta | Ƙarawa | Taurin Brinell (HB) |

| Maganin Zubar da Jini | 550 N/mm² | 240 N/mm² | Kashi 30% | ≤195 |

| Maganin Maganin | 500 N/mm² | 180 N/mm² | Kashi 35% | ≤185 |

Matsayin Samarwa namu

| mashaya | Ƙirƙira | Bututu | Takarda/Teri | Waya | Kayan aiki | |

| ASTM | ASTM B166 | ASTM B564 | ASTM B167/B163/B516/B517 | AMS B168 | ASTM B166 | ASTM B366 |

Walda na Inconel 600

Ana iya amfani da duk wani tsarin walda na gargajiya don walda Inconel 600 zuwa ga ƙarfe iri ɗaya ko wasu ƙarfe. Kafin walda, ana buƙatar dumamawa kafin lokaci kuma duk wani tabo, ƙura ko alama ya kamata a goge shi da goga na waya na ƙarfe. Ya kamata a goge kusan faɗin 25mm zuwa gefen walda na ƙarfe mai tushe har ya zama mai haske.

Ba da shawarar waya mai cikewa game da walda Inconel 600: ERNiCr-3

Nau'ikan samfura

-

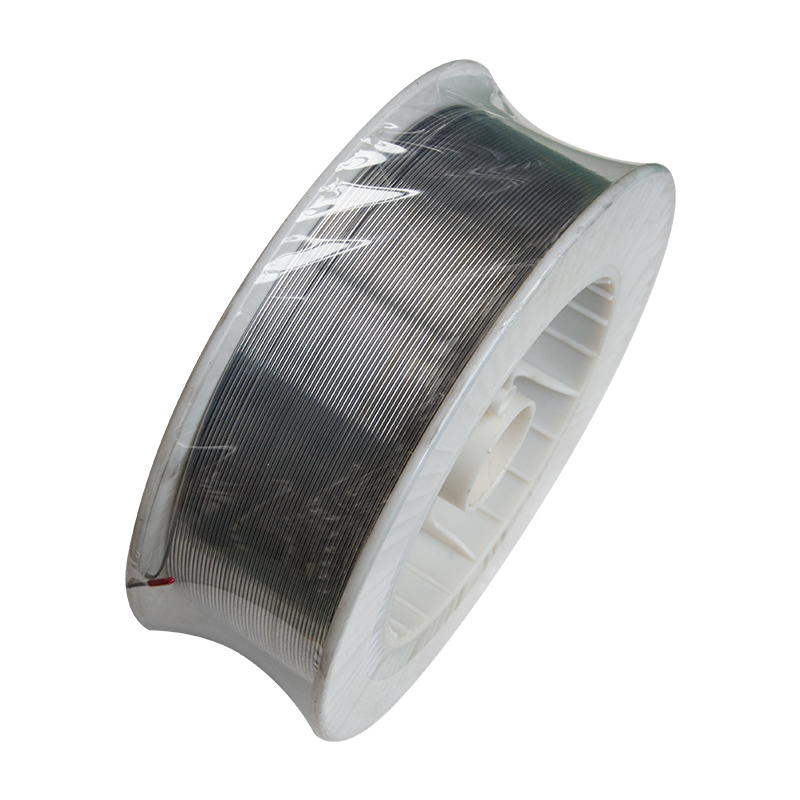

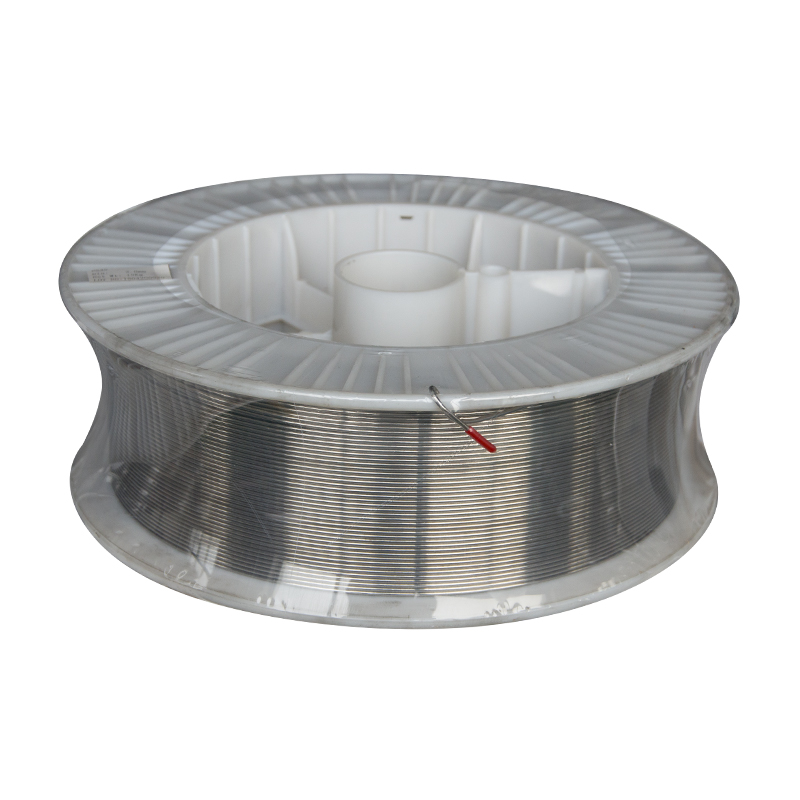

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama