Barka da zuwa gidajen yanar gizon mu!

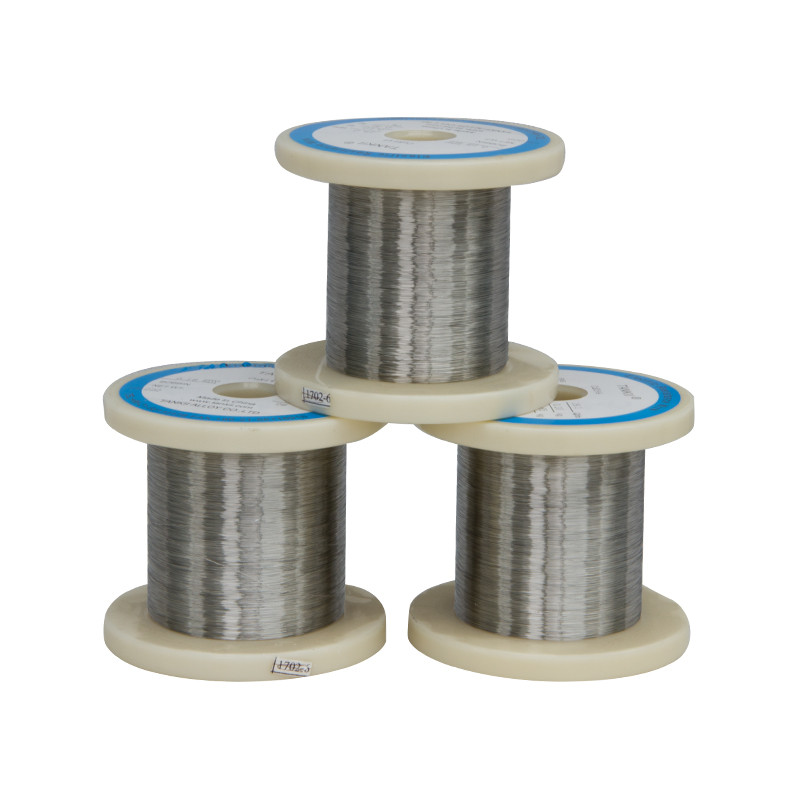

1j76 Ni76Cr2Cu5 Wayar Alloys Mai Taushi Mai Juyawa Ta Farko

Tsarin al'ada%

| Ni | 75~76.5 | Fe | Bal. | Mn | 0.3~0.6 | Si | 0.15~0.3 |

| Mo | - | Cu | 4.8~5.2 | Cr | 1.8~2.2 | ||

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Al'adar Injin da ta dace

| Ƙarfin bayarwa | Ƙarfin Taurin Kai | Ƙarawa |

| Mpa | Mpa | % |

| 980 | 1030 | 3~50 |

Halayen Jiki na Al'ada

| Yawan yawa (g/cm3) | 8.6 |

| Juriyar lantarki a 20ºC (Om*mm2/m) | 0.55 |

| Ma'aunin faɗaɗa layi (20ºC ~ 200ºC)X10-6/ºC | 10.3~11.5 |

| Ma'aunin ƙarfin maganadisu λθ/ 10-6 | 2.4 |

| Ma'aunin Curie Tc/ºC | 400 |

Abubuwan da ke tattare da maganadisu na ƙarfe masu ƙarfin aiki a cikin wurare masu rauni | |||||||

| 1J76 | Farkon shigar haske | Mafi girman ikon wucewa | Tilasta | Ƙarfin shigar da maganadisu mai cikawa | |||

| Zare/ledar da aka yi birgima da shi. Kauri, mm | μ0.08/ (mH/m) | μm/ (mH/m) | Hc/ (A/m) | BS/T | |||

| ≥ | ≤ | ||||||

| 0.01 mm | 17.5 | 87.5 | 5.6 | 0.75 | |||

| 0.1~0.19 mm | 25.0 | 162.5 | 2.4 | ||||

| 0.2 ~ 0.34 mm | 28.0 | 225.0 | 1.6 | ||||

| 0.35~1.0 mm | 30.0 | 250.0 | 1.6 | ||||

| 1.1 ~ 2.5 mm | 27.5 | 225.0 | 1.6 | ||||

| 2.6~3.0 mm | 26.3 | 187.5 | 2.0 | ||||

| waya mai sanyi da aka ja | |||||||

| 0.1 mm | 6.3 | 50 | 6.4 | ||||

| mashaya | |||||||

| 8-100 mm | 25 | 100 | 3.2 | ||||

| Yanayin maganin zafi 1J76 | |

| Kafofin watsa labarai masu wargaza | Yi amfani da injin tsotsa mai matsi wanda bai wuce 0.1Pa ba, sannan a yi amfani da sinadarin hydrogen mai matsi wanda bai wuce 40ºC ba. |

| Zafin jiki da ƙimar dumama | 1100~1150ºC |

| Lokacin riƙewa | 3~6 |

| Saurin sanyaya | Da zafin jiki na 100 ~ 200 ºC/h, za a sanyaya shi zuwa 600 ºC, sannan a sanyaya shi da sauri zuwa 300 ºC |

Rubuta saƙonka a nan ka aika mana da shi

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama