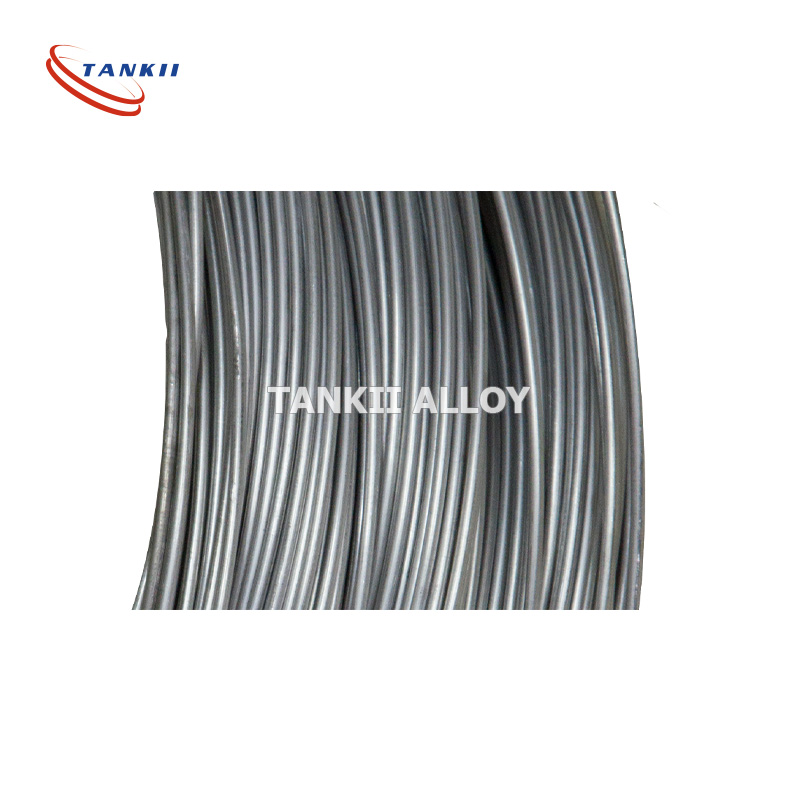

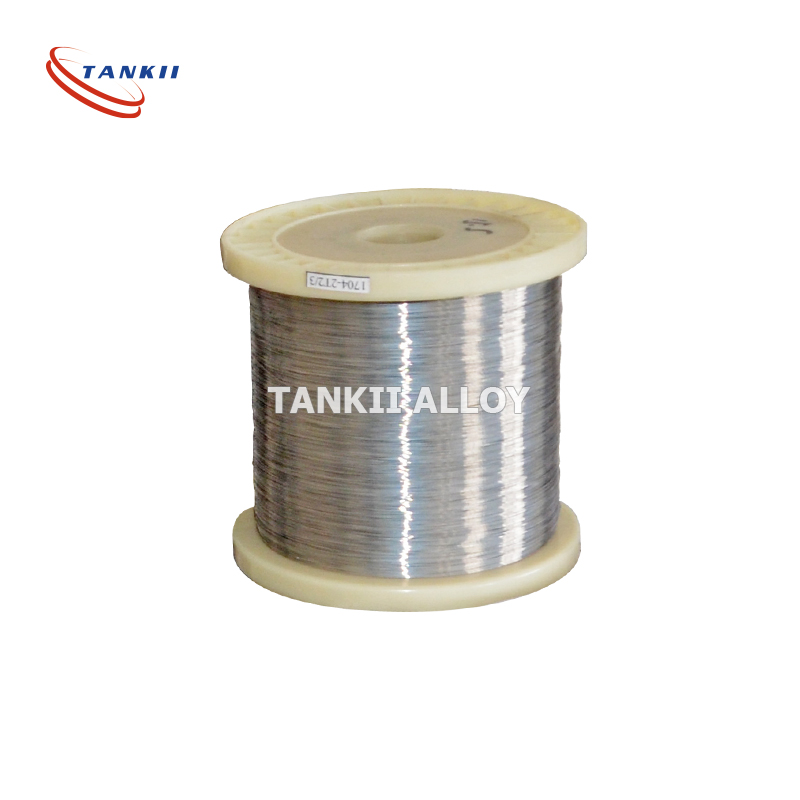

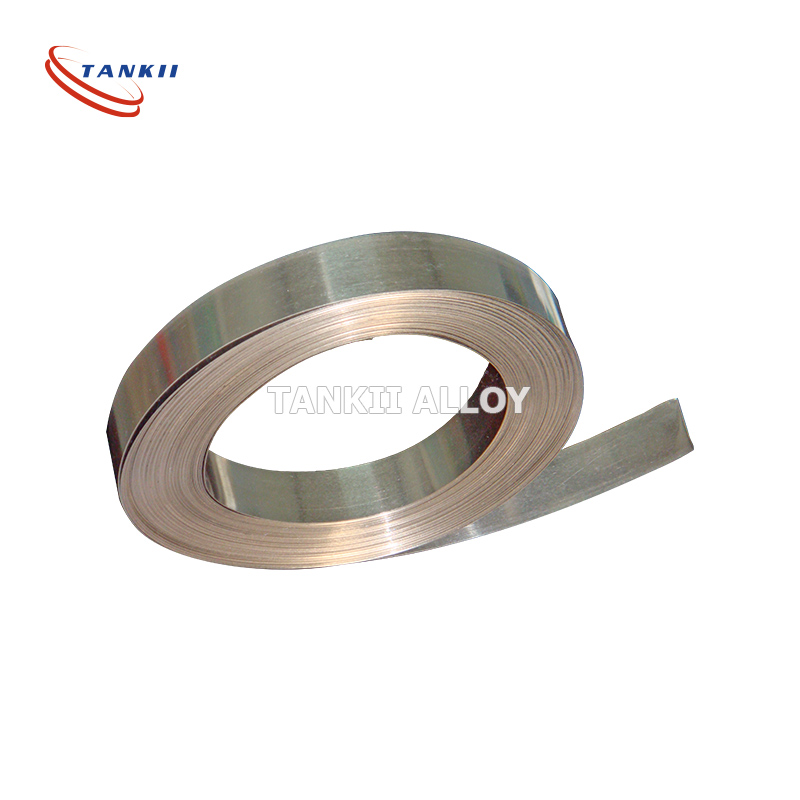

1400°C Babban Ingantaccen thermal HRE FeCrAl25/6 Alloy Heating Wire Spring SWG Standard

1400°C Babban Haɓakar zafiHRE FeCrAl25/6 Alloy Heating Wire Spring SWG Standard

TheFecral 25/6- HRE za a iya amfani da wutar lantarki tanda na yumbu masana'antu, metallurgical da kuma sinadaran masana'antu da kuma a duk aikace-aikace inda kuma shi ne ake bukata a sosai high aiki zafin jiki. Ana amfani da shi kuma ana bada shawarar har zuwa 1400 ° C.

Babban halayen fasaha na FeCrAl Alloy:

| Alamar Dukiya | 1Cr13Al4 | 1Cr21Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr25Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Babban bangaren sinadarai% | Cr | 12.0-12.5 | 17.0-21.0 | 19.0-22.0 | 20.5-23.5 | 23.0-26.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 2.0-4.0 | 5.0-7.0 | 4.2-5.3 | 4.5-6.5 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Ma'auni | Ma'auni | Ma'auni | Ma'auni | Ma'auni | Ma'auni | Ma'auni | |

| Re | Dace | Dace | Dace | Dace | Dace | Dace | Dace | |

| Ƙarin Nb:0.5 | Bugu Mo: 1.8-2.2 | |||||||

| Bangaren max. amfani da zafin jiki | 950 | 1100 | 1250 | 1250 | 1250 | 1350 | 1400 | |

| Matsayin narkewa | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1510 | |

| Girman g/cm3 | 7.40 | 7.35 | 7.16 | 7.25 | 7.10 | 7.10 | 7.10 | |

| Juriya μΩ·m,20 | 1.25± 0.08 | 1.23 ± 0.06 | 1.42± 0.07 | 1.35± 0.06 | 1.45± 0.07 | 1.45± 0.07 | 1.53± 0.07 | |

| Ƙarfin Tensile Mpa | 588-735 | 637-784 | 637-784 | 637-784 | 637-784 | 637-784 | 684-784 | |

| Adadin kari% | 16 | 12 | 12 | 12 | 12 | 10 | ||

| Mitar lankwasa maimaituwa | 5 | 5 | 5 | 5 | 5 | |||

| Mai sauri daga h/ | - | 80/1300 | 80/1300 | 50/1350 | ||||

| Takamaiman Zafi J/g. | 0.490 | 0.490 | 0.520 | 0.460 | 0.494 | 0.494 | 0.494 | |

| Haɗin Gudanar da Zafi KJ/Mh | 52.7 | 46.9 | 63.2 | 60.1 | 46.1 | 46.1 | 45.2 | |

| Ƙididdigar faɗaɗawa ta layiar aX10-6/ (20-1000) | 15.4 | 13.5 | 14.7 | 15.0 | 16.0 | 16.0 | 16.0 | |

| Hardness HB | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Karamin tsari | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | |

| Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Siffa:

Tare da tsawon rayuwar sabis.Zazzagewa da sauri.High thermal yadda ya dace. Yanayin zafin jiki. Za a iya amfani da shi a tsaye. Lokacin da ake amfani da shi a cikin ƙimar ƙarfin lantarki, babu wani abu mai canzawa. Yana da kariyar muhalli ta wayar dumama lantarki. Kuma madadin waya mai tsadar nichrome. Ana iya daidaita shi bisa ga bukatun abokin ciniki

FeCrAl alloys suna da kyau kwarai juriya da iskar shaka da kwanciyar hankali mai kyau wanda ke haifar da tsawon rayuwa.

Yawancin lokaci ana amfani da su a cikin abubuwan dumama wutar lantarki a cikin tanderun masana'antu da na'urorin gida.

Fe-Cr-Al alloy tare da babban juriya da zafin sabis fiye da wancan don gami da NiCr kuma yana da ƙarancin farashi.

Yankin aikace-aikace

Our kayayyakin da ake amfani da ko'ina a zafi magani kayan aiki, auto sassa, baƙin ƙarfe da kuma karfe masana'antu,

aluminum masana'antu, metallurgical kayan aiki, Petrochemical kayan aiki, gilashin inji, yumbu inji,

injinan abinci, injinan magunguna, da masana'antar injiniyan wutar lantarki.

Abubuwan Kemikal, %

| Alloy kayan | Abubuwan sinadaran% | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | wasu | |

| max (≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Huta | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Huta | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Huta | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Huta | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Huta | - |

| 0Cr19Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Huta | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Huta | Nb da 0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Huta | |

Rukunin samfuran

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 000 2421

-

Sama