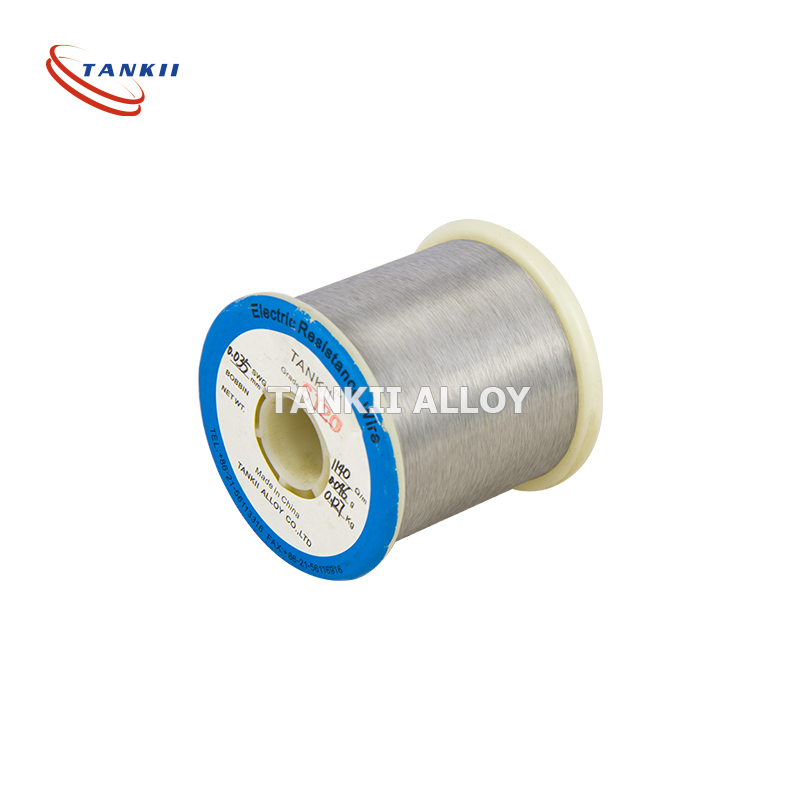

Ni90Cr10 NiCr 90/10 Nickel Chrome Alloy waya chromel Alumel Thermocouple Kan Sassan Kai

Ni90Cr10 Wayar NiCr90/10 mai gami da nickel chromewaya ta nichromesassan kan thermocouple

mai samar da kayayyaki na kasar Sin nichrome 90 Ni90

Ni90Cr10 wani ƙarfe ne na austenitic nickel-chromium (NiCr alloy) wanda ake amfani da shi a yanayin zafi har zuwa 1200°C (2190°F). An siffanta ƙarfen da juriya mai yawa, juriyar iskar shaka mai kyau da kuma kwanciyar hankali mai kyau. Yana da kyakkyawan juriya bayan amfani da shi da kuma kyakkyawan ƙarfin walda.

Ana amfani da Ni90Cr10 don abubuwan dumama wutar lantarki a cikin kayan aikin gida da tanderun masana'antu. Amfani da aka saba yi shine ƙarfe mai faɗi, injunan guga, na'urorin dumama ruwa, na'urorin ƙera filastik, ƙarfen solder, abubuwan bututun ƙarfe masu rufi da harsashi.

Saboda kyawawan halayen mannewa na surface oxide, Ni90C10 yana ba da ingantaccen tsawon rai na sabis idan aka kwatanta da ƙarfe masu gasa na nickel-chromium.

| Kayan aiki | Ni90Cr10 | Ni80Cr20 | Ni70Cr30 | Ni60Cr15 | Ni35Cr20 | Ni30Cr20 | |

| Tsarin aiki | Ni | 90 | Hutu | Hutu | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1.0 | ≤1.0 | Hutu | Hutu | Hutu | ||

| Matsakaicin zafin jiki°C | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Wurin narkewa ºC | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Yawan g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Juriyar yanayi a 20ºC((μΩ·m) | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | ||

| Ƙarawa a lokacin fashewa | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Takamaiman zafi J/g.ºC | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | ||

| Maida wutar lantarki ta thermal KJ/m.hºC | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | ||

| Faɗaɗa layukan layuka a×10-6/ (20~1000ºC) | 18 | 17 | 17 | 19 | 19 | ||

| Tsarin micrographic | Austenite | Austenite | Austenite | Austenite | Austenite | ||

| Sifofin maganadisu | Ba maganadisu ba | Ba maganadisu ba | Ba maganadisu ba | Mai rauni mai maganadisu | Mai rauni mai maganadisu | ||

girman:

OD: 0.3-8.0mm,

| Wayoyi Masu Juriya | ||

| RW30 | W.Nr 1.4864 | Nickel 37%, Chrome 18%, Iron 45% |

| RW41 | UNS N07041 | Nickel 50%, Chrome 19%, Cobalt 11%, Molybdenum 10%, Titanium 3% |

| RW45 | W.Nr 2.0842 | Nickel 45%, Tagulla 55% |

| RW60 | W.Nr 2.4867 | Nickel 60%, Chrome 16%, Iron 24% |

| RW60 | UN NO6004 | Nickel 60%, Chrome 16%, Iron 24% |

| RW80 | W.Nr 2.4869 | Nickel 80%, Chrome 20% |

| RW80 | UN NO6003 | Nickel 80%, Chrome 20% |

| RW125 | W.Nr 1.4725 | Baƙin ƙarfe, Chrome 19%, Aluminum 3% |

| RW145 | W.Nr 1.4767 | Baƙin ƙarfe, Chrome 20%, Aluminum 5% |

| RW155 | Baƙin ƙarfe, Chrome 27%, Aluminum 7%, Molybdenum 2% | |

Ana amfani da CHROMEL vs ALUMEL wajen rage iskar oxygen, rashin aiki ko bushewa. Fuskantar iskar gas ta iyakance ga ɗan gajeren lokaci. Dole ne a kare ta daga yanayin iskar oxygen mai sulfur da kuma iskar oxygen mai ɗan ƙarfi. Abin dogaro kuma daidai ne a yanayin zafi mai yawa. Chromel: Chromel wani ƙarfe ne na kimanin kashi 90% na nickel da chromium 10%. Ana amfani da shi wajen ƙera masu sarrafa zafi na ANSI Type E da Type K, na'urori don auna zafin jiki wanda ya ƙunshi masu sarrafa zafi guda biyu daban-daban.

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama