Barka da zuwa gidajen yanar gizon mu!

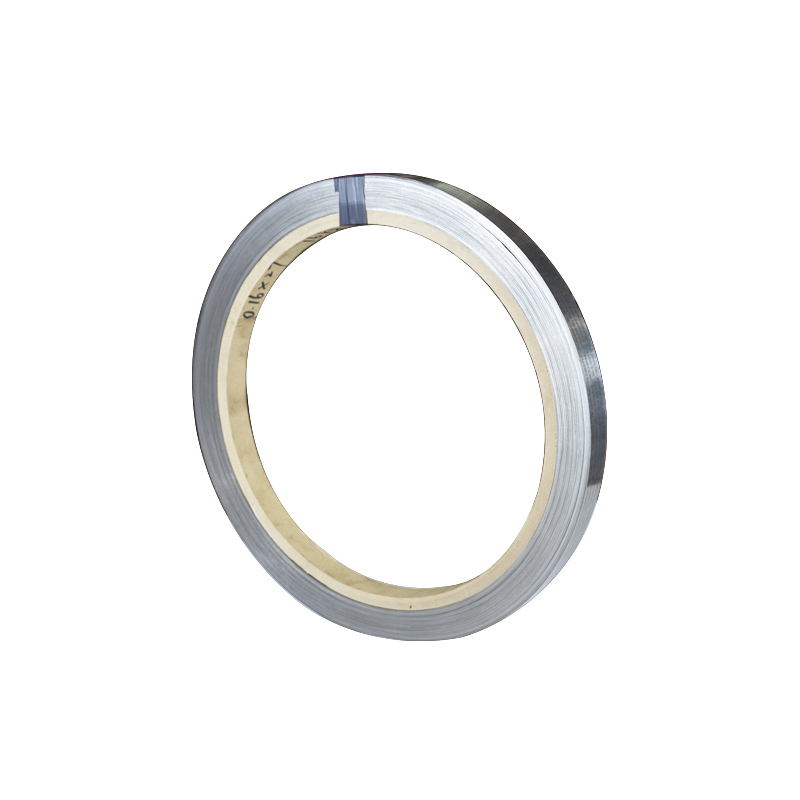

0.16mm x 27mm P675R/TM2/TB20110 Bimetallic Strip ASTM B388 Mai Saurin Amsawa da Dorewa Mai Sauri

Bayanin Samfurin

Zirin P675R (Kauri 0.16mm × Faɗin 27mm)

Bayanin Samfuri

Tsarin P675R bimetallic (0.16mm×27mm), wani kayan aiki mai inganci daga Tankii Alloy Material, wani yanki ne na musamman wanda ya ƙunshi ƙarfe biyu daban-daban tare da ma'aunin faɗaɗa zafi daban-daban - an haɗa shi da ƙarfi ta hanyar fasahar haɗin zafi da yaɗuwa ta mallakarmu. Tare da madaidaicin ma'aunin siriri na 0.16mm da faɗin 27mm na yau da kullun, an inganta wannan tsiri don ƙananan aikace-aikacen da ke da sauƙin jure yanayin zafi, inda daidaitaccen aikin zafi, daidaiton girma, da ƙirar adana sarari suke da mahimmanci. Ta hanyar amfani da ƙwarewar Huona a cikin sarrafa haɗin bimetallic, matakin P675R yana ba da daidaiton aikin nakasa mai jure yanayin zafi, yana yin aiki fiye da tsiri bimetallic na yau da kullun a cikin jituwa tsakanin na'urori masu ƙwaƙwalwa da juriya ga gajiya na dogon lokaci - yana mai da shi ya dace da ƙananan thermostats, masu kare zafi fiye da kima, da sassan diyya na zafin jiki daidai.

Tsarin Ma'auni da Tsarin Mahimmanci

- Samfurin Sashi: P675R

- Bayanin Girma: Kauri 0.16mm (juriya: ±0.005mm) × faɗin 27mm (juriya: ±0.1mm)

- Tsarin Haɗaɗɗen Siffa: Yawanci yana da "layin faɗaɗawa mai yawa" da kuma "layin faɗaɗawa mai ƙarancin girma", tare da ƙarfin yanke fuska ≥160 MPa

- Ma'aunin da ya dace: Yana bin ƙa'idodin GB/T 14985-2017 (ƙa'idar Sinanci don zare biyu na ƙarfe) da IEC 60694 don abubuwan sarrafa zafi

- Mai ƙera: Tankii Alloy Material, wanda aka ba da takardar shaida ga ISO 9001 da ISO 14001, tare da na'urar mirgina sirara da kuma iya yankewa daidai.

Manyan Fa'idodi (idan aka kwatanta da Rigunan Bimetallic na Janar)

Tsarin P675R (0.16mm×27mm) ya shahara saboda siraran ma'auni da kuma sauƙin faɗi mai tsauri:

- Daidaito Mai Sirara: Yana kiyaye kauri iri ɗaya (0.16mm) kuma babu rabuwar fuska tsakanin fuska - ko da bayan zagayowar zafi 5000 (-40℃ zuwa 180℃) - yana magance matsalar gama gari ta tsiri mai sirara mai ma'auni biyu (≤0.2mm) wanda ke iya juyawa ko rabuwar layuka.

- Daidaitaccen Yanayin Zafi: Na'urar da aka sarrafa (lanƙwasa da zafin jiki ya haifar) na 9-11 m⁻¹ (a 100℃ vs. 25℃), tare da karkacewar zafin jiki ≤±1.5℃—mai mahimmanci ga ƙananan na'urori (misali, masu kare zafi mai yawa na batirin) inda iyakokin zafin jiki suke da kunkuntar.

- Faɗin da aka Kayyade don Samarwa ta atomatik: Faɗin da aka daidaita na 27mm ya dace da girman mayukan buga takardu na micro-stamping, yana kawar da buƙatar yankewa na biyu da rage sharar kayan da kashi ≥15% idan aka kwatanta da mayukan faɗin da aka saba.

- Kyakkyawan Inganci: Siraran ma'aunin 0.16mm yana ba da damar lanƙwasawa cikin sauƙi (mafi ƙarancin radius mai lanƙwasa ≥2× kauri) da yanke laser zuwa ƙananan siffofi (misali, ƙananan hulɗar thermostat) ba tare da fashewa ba—wanda ya dace da layukan haɗuwa masu sauri-sauri.

- Juriyar Tsatsa: Maganin shafawa na musamman a saman fata yana ba da juriya ga feshin gishiri na awanni 72 (ASTM B117) ba tare da tsatsa mai ja ba, wanda ya dace da yanayin danshi (misali, na'urori masu auna zafin jiki na na'urar da za a iya sawa).

Bayanan Fasaha

| Siffa | Darajar (Na yau da kullun) |

|---|---|

| Kauri | 0.16mm (juriya: ±0.005mm) |

| Faɗi | 27mm (juriya: ±0.1mm) |

| Tsawon kowace Naɗi | 100m - 300m (ana iya yankewa zuwa tsayi: ≥50mm) |

| Rabon Faɗaɗa Ma'aunin Zafi (Babban/Ƙaramin Layer) | ~13.6:1 |

| Yanayin Zafin Aiki | -70℃ zuwa 350℃ |

| Matsakaicin Zafin Aiki | 60℃ - 150℃ (ana iya customize ta hanyar daidaita rabon gami) |

| Ƙarfin Ragewa Tsakanin Fuska | ≥160 MPa |

| Ƙarfin Taurin Kai (Transverse) | ≥480 MPa |

| Ƙarawa (25℃) | ≥12% |

| Juriya (25℃) | 0.18 – 0.32 Ω·mm²/m |

| Taurin saman (Ra) | ≤0.8μm (ƙarshen niƙa); ≤0.4μm (ƙarshen da aka goge, zaɓi ne) |

Bayanin Samfura

| Abu | Ƙayyadewa |

|---|---|

| Ƙarshen Fuskar | gama niƙa (ba ya amfani da iskar oxygen) ko gamawa mai lalacewa (don juriya ga tsatsa) |

| Faɗi | ≤0.08mm/m (mahimmanci don daidaiton ƙananan tambari) |

| Ingancin Haɗi | Haɗin fuska 100% (babu gurɓatattun abubuwa sama da 0.05mm², an tabbatar da su ta hanyar duba X-ray) |

| Ƙarfin daidaitawa | Zabin da za a yi amfani da shi a cikin tin-plating (kauri: 3-5μm) don haɓaka ƙarfin soldering tare da Sn-Pb/ba tare da gubar ba |

| Marufi | An rufe injin tsabtacewa a cikin jakunkunan foil na aluminum masu hana iskar shaka tare da abubuwan bushewa; maƙallan filastik (diamita 150mm) don hana lalacewar tsiri |

| Keɓancewa | Daidaita zafin aiki (30℃ – 200℃), rufin saman (misali, nickel-plating), ko siffofi da aka riga aka buga (ga kowane fayilolin CAD na abokin ciniki) |

Aikace-aikace na yau da kullun

- Ƙaramin Kula da Zafin Jiki: Ƙananan thermostats don na'urori masu sawa (misali, agogon hannu mai wayo), ƙananan kayan aikin gida (misali, ƙananan injinan dafa shinkafa), da na'urorin likitanci (misali, masu sanyaya insulin).

- Kariyar Zafi Mai Yawa: Ƙananan na'urorin katse wutar lantarki na batirin lithium-ion (misali, bankunan wutar lantarki, batirin kunne mara waya) da ƙananan injina (misali, injinan drone).

- Diyya Mai Daidaito: Na'urorin auna zafin jiki na na'urorin auna MEMS (misali, na'urorin auna matsin lamba a wayoyin komai da ruwanka) don daidaita kurakuran aunawa da faɗaɗa zafi ke haifarwa.

- Kayan Lantarki na Masu Amfani: Masu kunna zafi don sarrafa hasken baya na allon kwamfutar tafi-da-gidanka da masu daidaita zafin fis ɗin fis ɗin fis.

- Ƙananan Na'urori Masu Masana'antu: Ƙananan maɓallan zafi don na'urori masu auna zafin jiki na IoT (misali, na'urori masu auna zafin jiki/danshi na gida mai wayo) da ƙananan sassan motoci (misali, na'urorin auna zafin jiki na tsarin mai).

Kayan Tankii Alloy yana sanya kowane tsari na sandunan bimetallic na P675R (0.16mm × 27mm) zuwa ga gwaji mai tsauri: gwaje-gwajen yanke haɗin fuska, gwaje-gwajen kwanciyar hankali na zafi mai zagaye 1000, duba girma ta hanyar micrometry na laser, da daidaita zafin jiki. Ana samun samfuran kyauta (50mm × 27mm) da cikakkun rahotannin aiki (gami da lanƙwasa zafin jiki da lanƙwasa) akan buƙata. Ƙungiyarmu ta fasaha tana ba da tallafi na musamman - kamar inganta Layer na alloy don takamaiman yanayin zafi na kunnawa da jagororin tsarin micro-stamping - don tabbatar da cewa tsiri ya cika ainihin buƙatun aikace-aikacen da aka tsara daidai.

Rubuta saƙonka a nan ka aika mana da shi

Nau'ikan samfura

-

Waya

-

Imel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sama